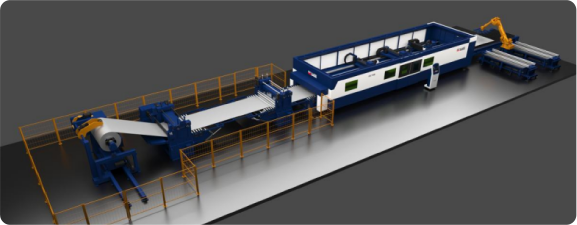

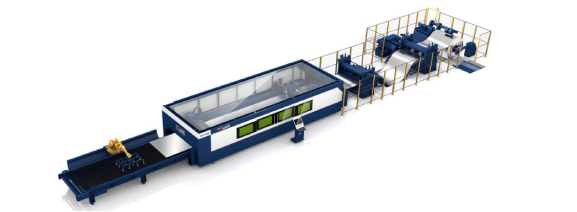

In today's highly competitive manufacturing environment, achieving greater efficiency and precision is crucial forsuccess. Smart, automated solutions that optimize workflows and maximize productivity are no longer optional-they areessential. The Han's GRC, Series Rolled Material Laser Cutter line is a game-changing solution, offering an integratedsystem that combines unroling, leveling, marking, cutting, and stacking into one seamless process. Renowned for itsflexibility and automation, the GRc Series has earned its reputation as the "King of Rolled Materials".

Key Features of the GRC Series Rolled Material Laser Cutter Line

Versatile Cutting Modes with Multi-Head Configurations

The GRC Series Laser Cutter Line provides unparalleled versatility with multiple cutting head configurations, allowing forhighly flexible operations, Depending on your production needs, you can choose from single, double, triple, or quadruplecutting head setups, each designed to handle different tasks efficiently.

Double-Head Cutting for Complex Shapes

The double-head configuration allows for rapid, precise cutting of iregularly shaped components, all in one pass. Thisreduces processing time and enhances production efficiency.

Triple-Head Cutting for Integrated Marking and Cutting

Add a laser marking head to the double-head setup, enabling simultaneous marking and cutting. This integration elimi.

nates the need for separate marking operations, boosting overall productivity.

Quadruple-Head Cutting: The Material Beast

With four cutting heads working simultaneously, the GRC Series maximizes cutting speed and efficiency. Choose fromsingle, double, triple, or guadruple cutting modes to suit the diverse demands of your production line.

Automated Unloading for Enhanced Efficiency Automation is at the heart of the GRc Series Laser Cutter Line, making theunloading process faster and more efficient. The system features multiple unloading options, such as robotic suction armsand gantry suction mechanisms, to ensure smooth and precise material handling.

Robotic Suction Arm Unloading

The robotic arm, paired with advanced nesting CAM software, ensures precise unloading and stacking, minimizing manualintervention, its efficient setup mode also shortens teachina time, speedina up the entire unloadina process

Advanced Stacking Capabilities

The system can handle stacked parts with ease, improving organization and reducing labor costs.

Intelligent and Open CNC System The GRCSeries is powered by the Han's SMC Open CNC System, offering unmatched precision and flexibility. Key features include:

1.Independent or synchronized edge detection for multiple cutting heads

2.Flexible multi-head synchronized processing

3.Automated execution of production plans

Support for secondary development, allowing for customization of the system to meet specific manufacturing require-ments

This inteligent CNC svstem guarantees high-efficiency operations, ensuring that your production line can handle complextasks with ease and precision.

Powerful Nesting Software for Maximum Performance The GRC Series incorporates Han's Laser proprietary nesting soft.ware, which enhances overall productivity by optimizing material usage and minimizing waste. Key benefits include:

1.Supports multiple import methods for part programs

2.Highly efficient automatic layout capabilities, ideal for long production runs (over 50 meters)

3.0ne-click export of all part programs for seamless integration

Intuitive, user-friendly design with "what-you-see-is-what-you-get" functionality

This advanced software simplifies the nesting process, allowing for faster setups and improved material optimization.

One-Step Processing: From Rolled Material to Finished Product The GRC Series Laser Cutter Line streamlines the entiremanufacturing process, seamlessly transitioning from unrolling to cutting, marking, and stacking all in one integratedworkflow. This one-step processing eliminates the need for manual handling and separate stages, reducing labor costsand improving overall production speed.

Why Choose the GRc Series Laser Cutter Line?

The GRC Series is more than just a laser cutter-it is a comprehensive solution designed to transform your manufacturingline into a hub of efficiency and innovation. From its versatile cutting heads to its intelligent automation and advancedsoftware, the GRC Series offers unmatched flexibility, speed, and precision.

Advantages of the GRC Series Rolled Material Laser Cutter Line

• Maximized Eficiency: Multi-head configurations, synchronized processing, and intelligent unloading minimize downtime

and increase throughput.

• Precision and Flexibility: Advanced CNC control, integrated laser marking, and customizable cutting modes ensureaccurate results across various production scenarios.

• Cost Reduction: Automated processes and optimized material nesting reduce manual labor and waste, cutting opera-tional costs.

• Future-Proof Technology: With support for secondary development and custom manufacturing needs, the GRc Series isbuilt to grow with your business.

Empower Your Manufacturing with the GRC series

Upgrade your production line with the GRc Series Rolled Material Laser Cutter line and unlock the future of laser cuttingtechnology. With its powerful automation, precision cutting capabilities, and advanced software, the GRc Series isdesigned to meet the demands of modern manufacturing, making it the ultimate choice for companies looking to enhancetheir cutting operations.

Previous

Previous

LET’S TALK

LET’S TALK