Advantages of Laser Welding

MPS-HW series hand-held laser welding machine has many advantages, such as high welding precision, fast speed, pollution-free, wide range of welding materials, etc. Zero-based operators can learn in 30 minutes. The welding process does not produce waste gas and is not harmful to human body. There is no special requirement for gas, air compressor gas can be used.

•Simple, easy to learn, flexible and convenient. Small-sized, simple in training and easy to operation.

• Support multi-dimensional welding. Low cost. No need for a fine welding work table, less consumables, lower running cost and maintenance cost.

•Labor saving. Handheld laser welding is fast, 5-10 times faster than traditional welding, and one machine can save at least 2 welders a year; The welded seam is smooth and beautiful, reducing the polishing process, saving time and cost;

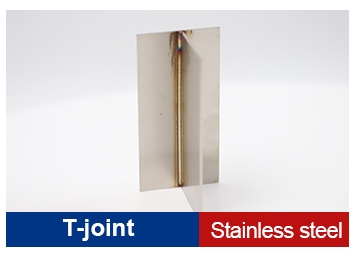

•Good quality. The laser welding work piece is free of deformation and welding scar, the welding is firm.

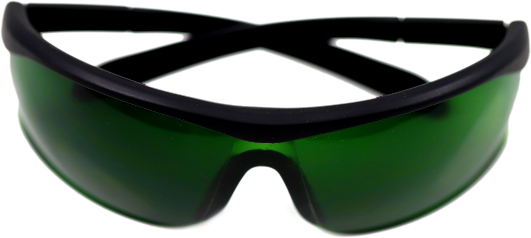

•Safety protection. It has contact safety protection function to avoid accidental light emission, making sure light emission welding after contact with metal to keep safety. Equipped with laser protective glasses, which shall be worn during welding

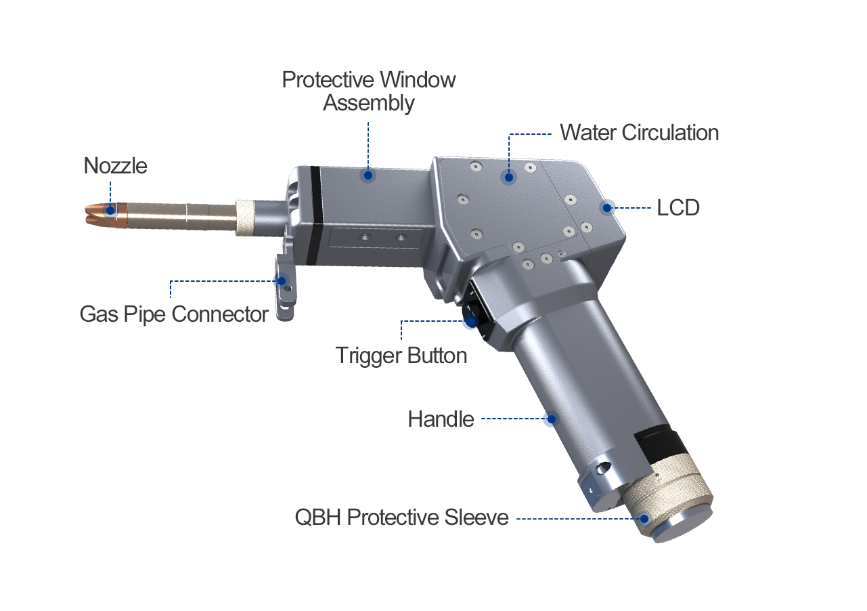

Welding-head

Only when the copper nozzle of the welding head contacts the workpiece and the button switch is pressed at the same time, the welding head can start to work. Avoid accidental lighting emission caused by mistakes.

Welding Nozzle

Different welding copper nozzles shall be replaced according to different weld forms.

Full Automatic Wire Feeder

Welding wire diameter 1.0mm, 1.2mm, 1.6mm

Laser Goggles

A special glasses that can prevent or reduce the harm of laser to human eyes. It is an efficient and safe goggles, which is suitable for a variety of lasers. The laser goggles are comfortable, beautiful, safe and reliable to wear.

MPS-HW Series

Laser Source Power

Fiber Length

Dimensions (L x W x H)

Machine Weight

Welding Head Weight

Working Voltage

Protective Gas Interface

Total Power

Weldable Material

Weld Thickness

Working Temperature

Storage Environment

1000w

≥10m (Customizable)

600mm×950mm×1000mm

300kg

1.0kg

220V ⁄ 380V

6mm Quick Plug

3kw

Stainless steel ⁄ Galvanized sheet ⁄ Aluminum alloy

1.5mm ⁄ 2.5mm ⁄ 3.5mm

5 ℃~ 40 ℃ (Anti-freeze is needed in low temperature environment.)

Temperature :10 ℃~ 60 ℃ (Emptying the water tank at low temperature.)

Humidity: 30% ~ 75% RH (No corrosive gas.)

1500w

≥10m (Customizable)

600mm×950mm×1000mm

300kg

1.0kg

220V ⁄ 380V

6mm Quick Plug

3kw

Stainless steel ⁄ Galvanized sheet ⁄ Aluminum alloy

1.5mm ⁄ 2.5mm ⁄ 3.5mm

5 ℃~ 40 ℃ (Anti-freeze is needed in low temperature environment.)

Temperature :10 ℃~ 60 ℃ (Emptying the water tank at low temperature.)

Humidity: 30% ~ 75% RH (No corrosive gas.)

2000w (More Optional)

≥10m (Customizable)

600mm×950mm×1000mm

300kg

1.0kg

220V ⁄ 380V

6mm Quick Plug

3kw

Stainless steel ⁄ Galvanized sheet ⁄ Aluminum alloy

1.5mm ⁄ 2.5mm ⁄ 3.5mm

5 ℃~ 40 ℃ (Anti-freeze is needed in low temperature environment.)

Temperature :10 ℃~ 60 ℃ (Emptying the water tank at low temperature.)

Humidity: 30% ~ 75% RH (No corrosive gas.)

contact us

LET’S TALK

LET’S TALK