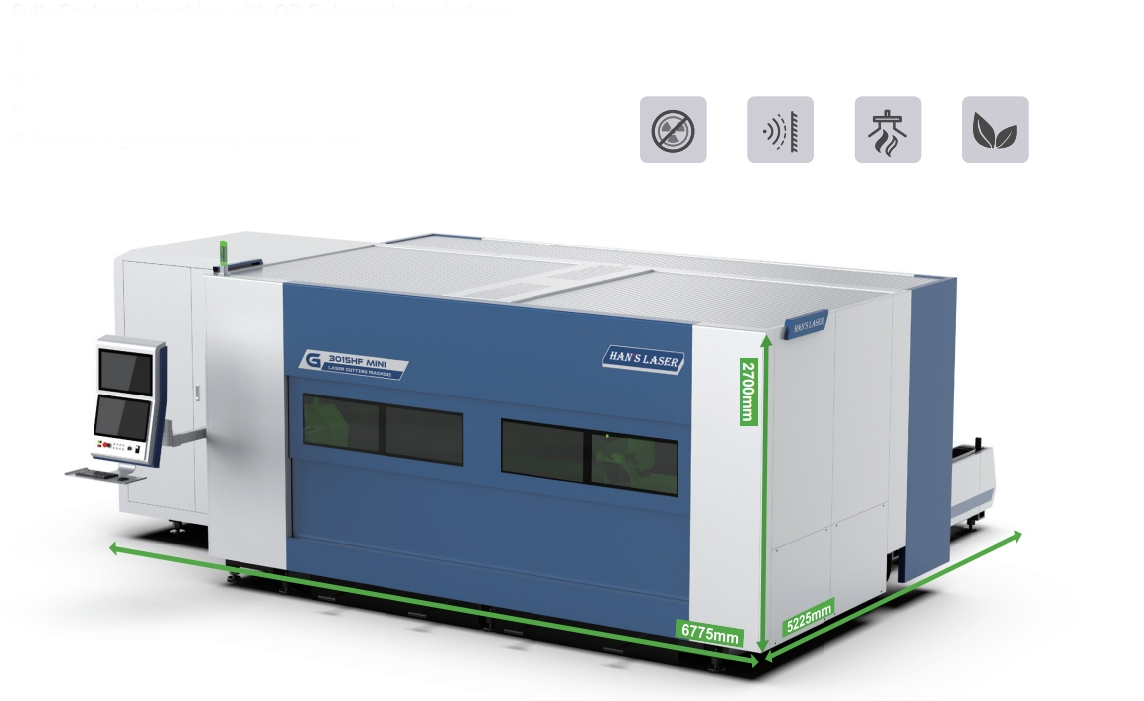

Laser Safety

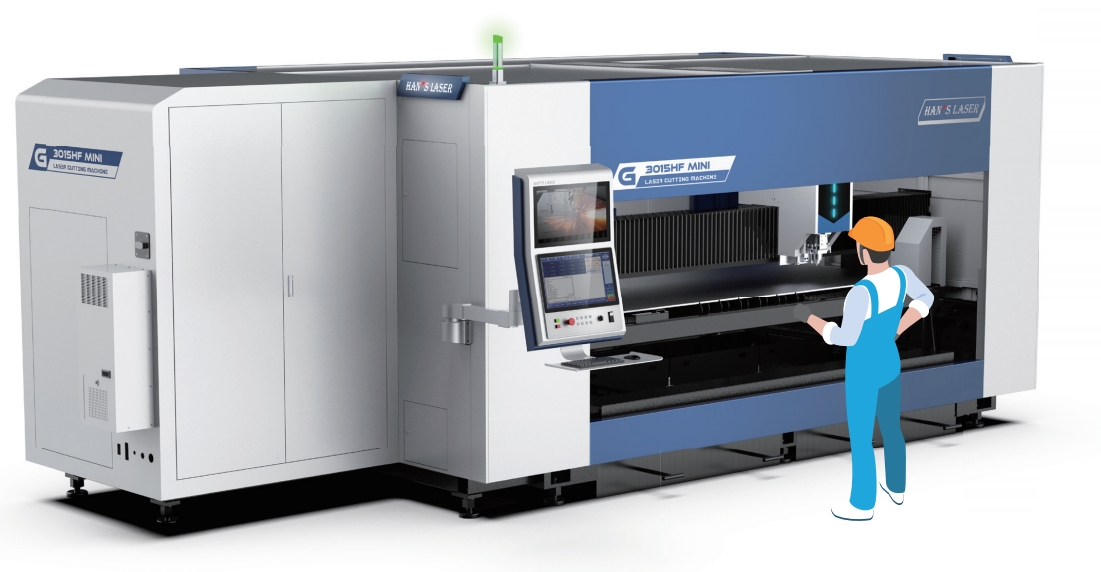

Fully enclosed machine with OD 5+ laser glass windows:

•Protect the eyes and skin from laser radiation;

•Reduce the noise pollution;

•Reduce the cutting smoke pollution;

•Provide a good working environment;

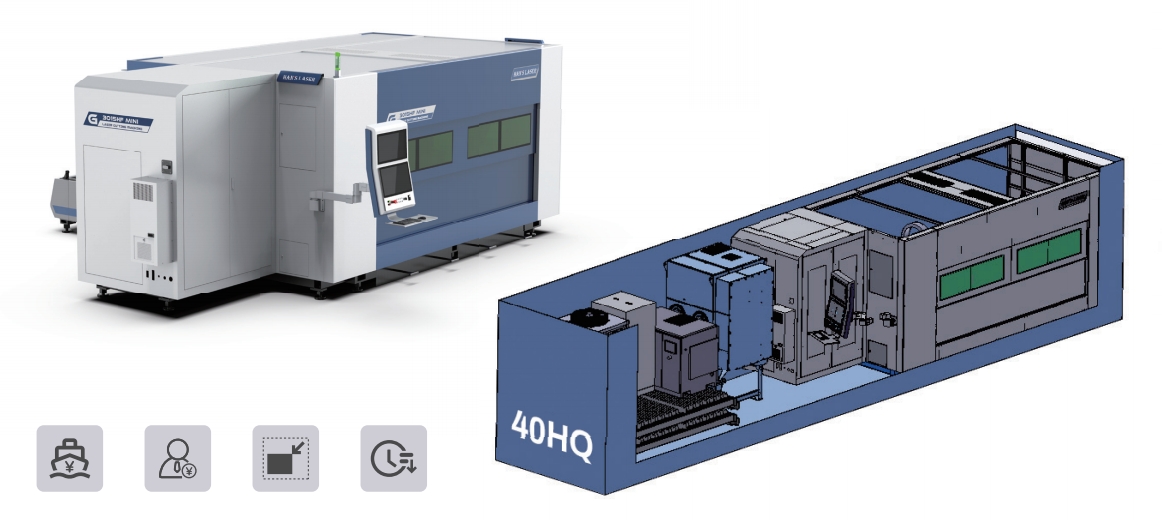

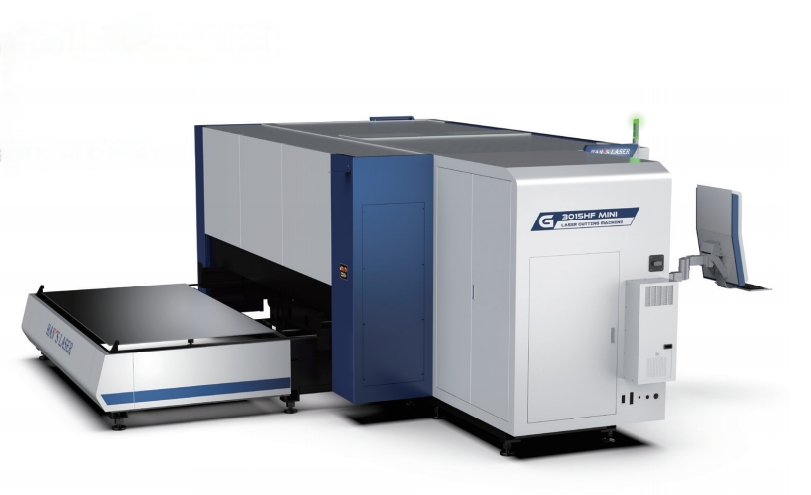

25% Space Saving

Compact design with maintenance-friendly access.

Electrical cabinet ⁄ laser source ⁄ pneumatic system ⁄ lubrication system ⁄ table Drive motors all integrated in main Frame, is flexible in placement, easy to install and maintain, effectively improves the utilization rate of the production space, reduce machine footprint, saving shipping costs.

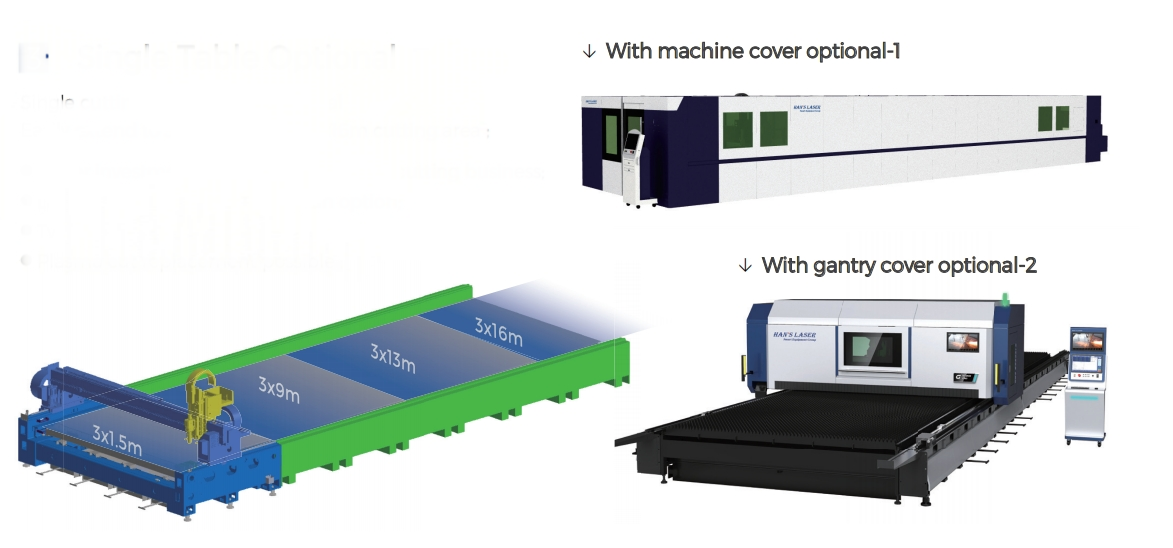

Single Table Optional

Single cutting table 3x1.5m optional

Easily extend to 3x9m ⁄ 3x13m ⁄ 3x16m cutting area ;

•Lower investment into high power laser cutting business;

•Lager cutting area available as an option;

•Two types of machine cover

•Plasma cut replacement possible ;

Ultra-High Power Suitable

Hollow structure machine bed (G3015 HF Mini);

Avoid the risk of high power lasers heat deformation;

Higher Power leads to Higher productivity.

Work Environment Friendly

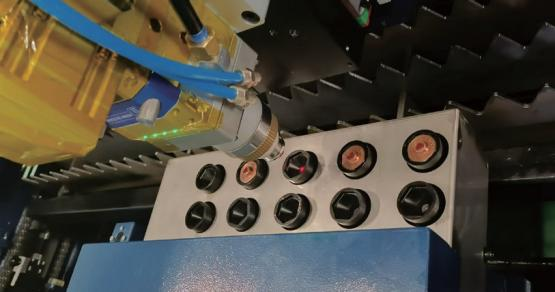

Separation dust suction system

Multi-zone suction,good dust removal effect, reduce the risk of contamination of the cutting head.

Heavy Load Capacity for Thick Material

Stronger Exchange Table Design

•Ensure good cutting quality ;

•Ergonomically loading & unloading for small pieces.

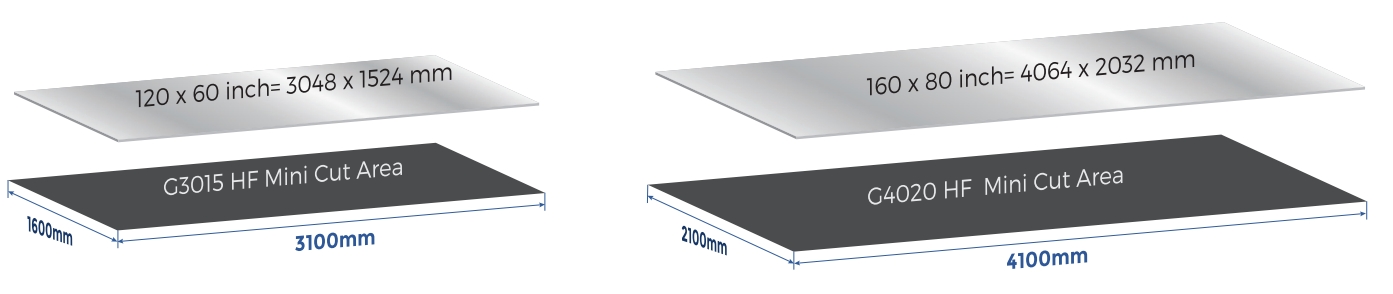

Larger Cutting Area

Increased cutting area,be able to cut AS (American standard) sheet in “inch” size

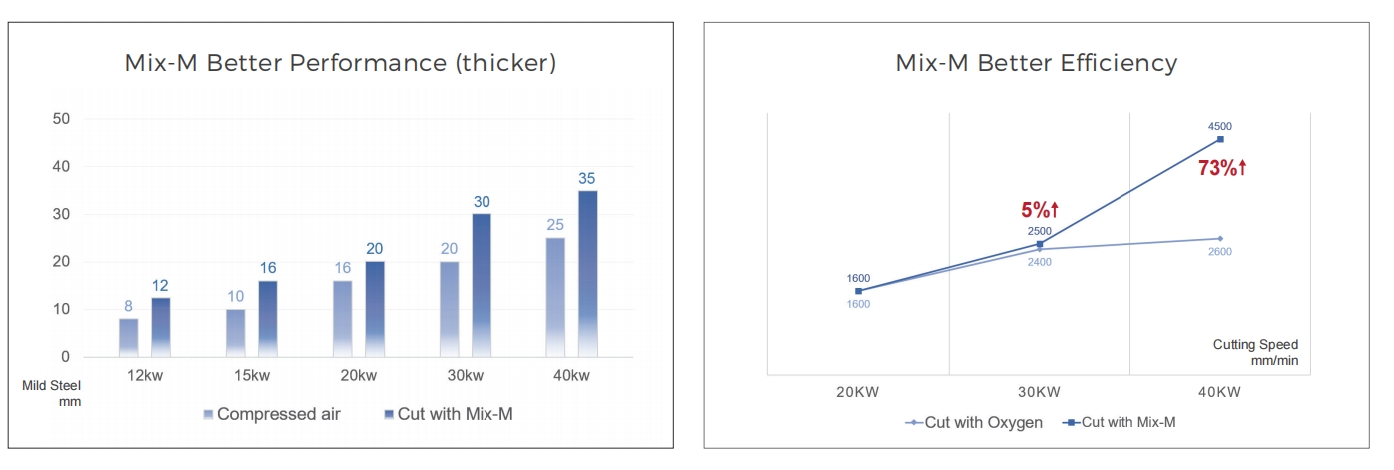

Lower Gas Consumption

Low N2 pressure cut

Faster cutting speed,less cutting time of the same batch, up to 67% Gas Saving.

HF Mini Series

Working Area [mm]

Max.Axis positioning speed(X/Y)

Max.Acceleration

Precision

Repetitiveness

Max.sheet weight

Available laser power

3100mmx1600mm

169m/min

1.7g

0.03mm

0.02mm

2150kg/table

6kW ⁄ 12kW ⁄ 20kW ⁄ 30kW ⁄ 40kW

4100mmx2100mm

169m/min

1.7g

0.03mm

0.02mm

3840kg/table

6kW ⁄ 12kW ⁄ 20kW ⁄ 30kW ⁄ 40kW

contact us

LET’S TALK

LET’S TALK