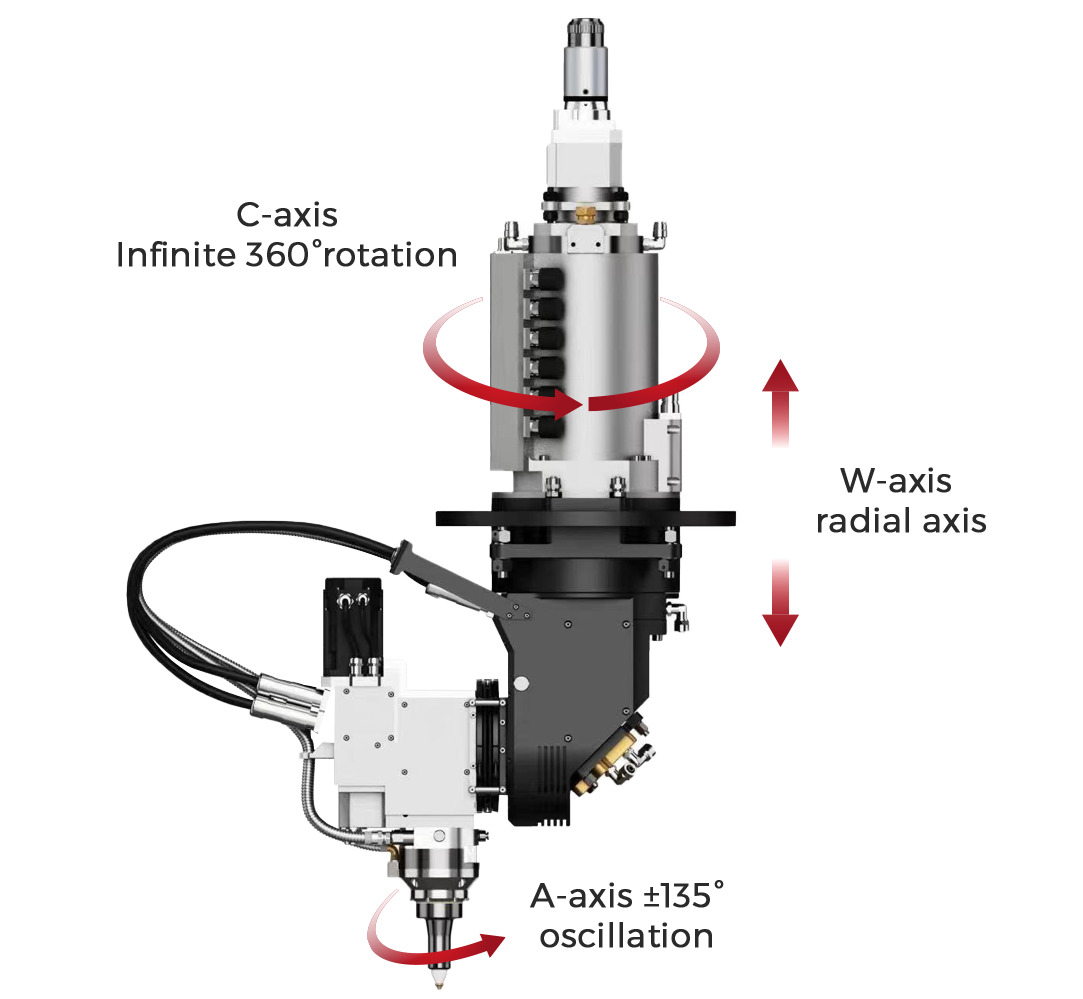

Lower Cutting Head Weight

The weight of the cutting head is reduced from 45 kg to less than 30 kg. It improves the overall performance of the cutting head by 15%.

3D Spatial Collision Avoidance

A-axis features an anti-collision mode with 360° protection.

W-axis is equipped with a high-sealing dustproof structure, prolonging the service life of the lens in harsh environments.

These features improves the dynamic performance,enhance equipment stability and help reduce operational costs.

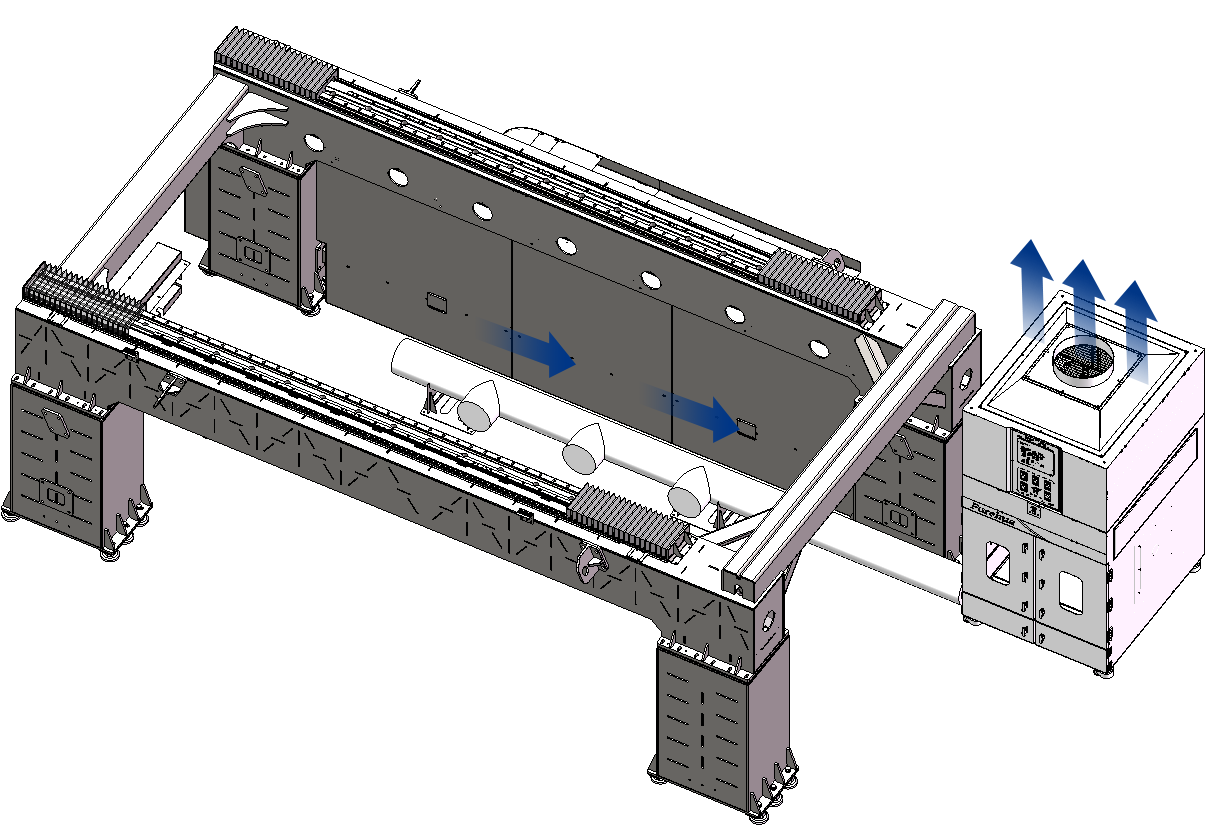

Work Environment Friendly

High-Efficiency Dust Removal: Integrated collector near machine guard with direct air duct linkage ensures resistance-free extraction.

Dual Protection: Shields precision components from dust while reducing emissions (<5mg/m³), promoting eco-friendly operation and worker safety.

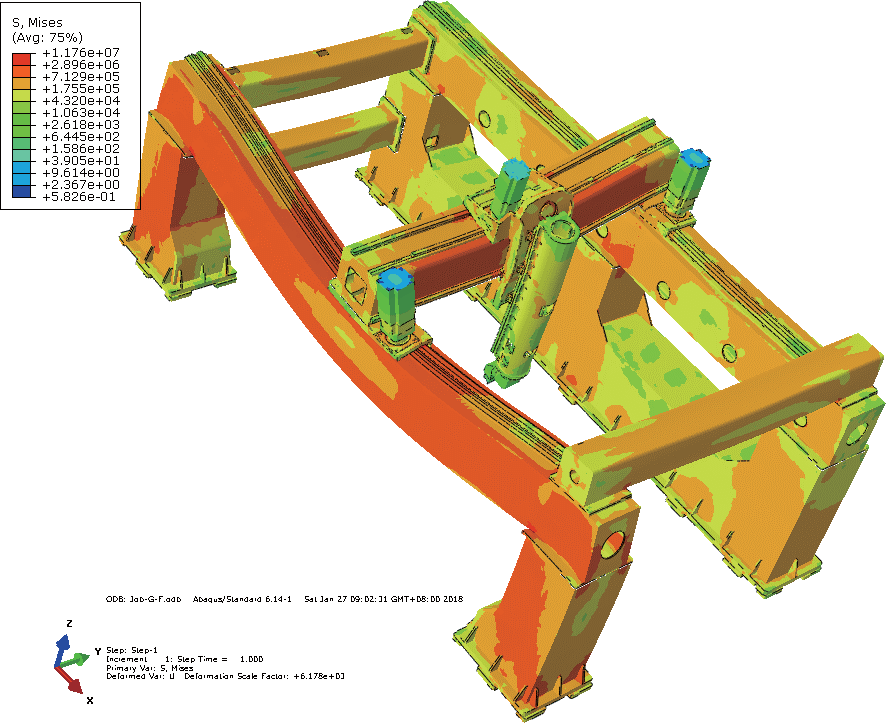

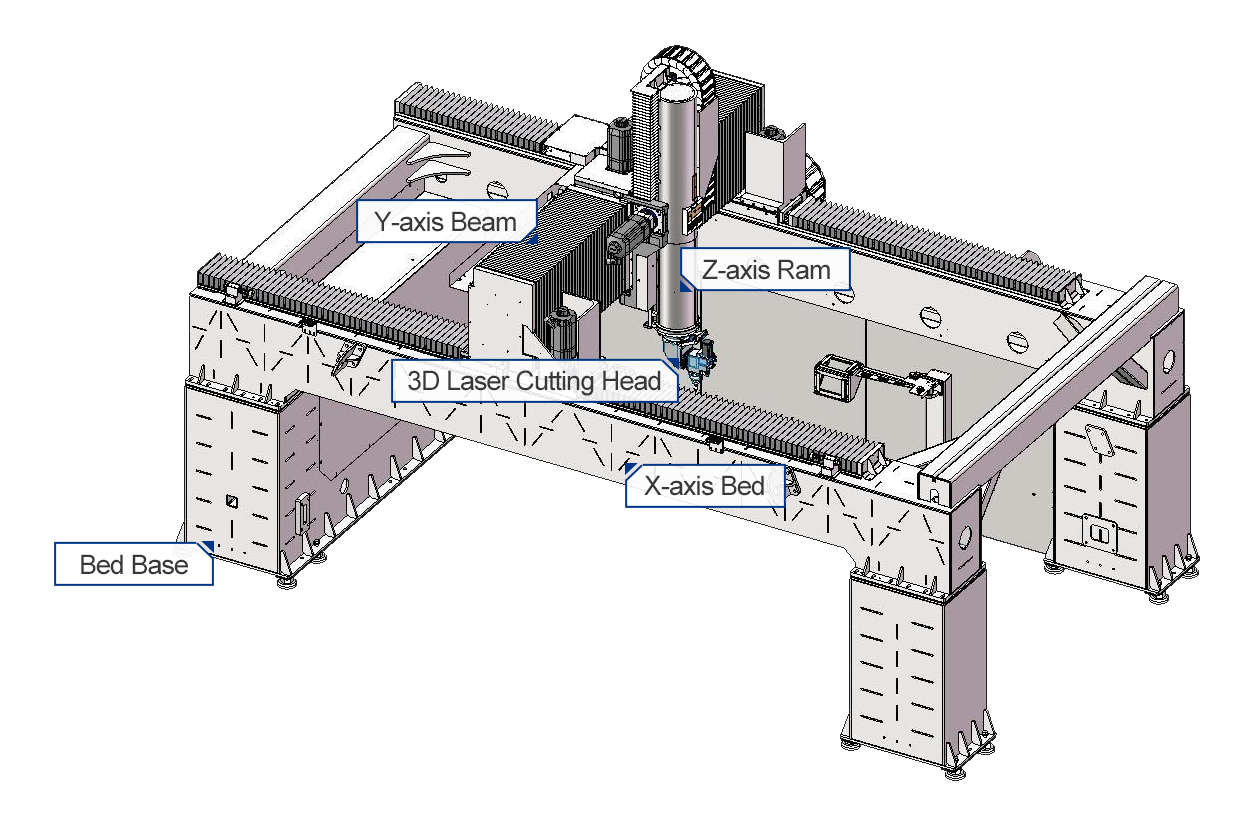

High Stability

The unique U-shaped base fixing structure developed by Han's Laser provides a large cross-sectional area, ensuring rigidity and stability of the machine bed, which reduces the risk of distortion during operations.

Dual Safety Protection

•Equipped with safety guardrails and grating to ensure the safety of workers during workpiece loading and unloading.

•These features ensure secure operation while maintaining workflow efficiency.

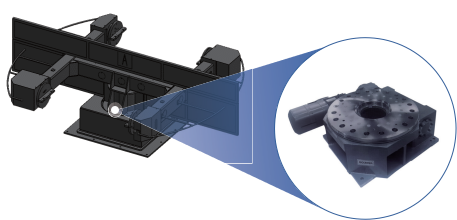

Duplex Rotary Table

· The table operates via a rotation exchange mechanism for high-efficiency operation.

· Safety grating in the lowering area ensures operator safety during loading and unloading.

· Equipped with an air line connection block and aviation connectors to ensure secure and proper clamp connections.

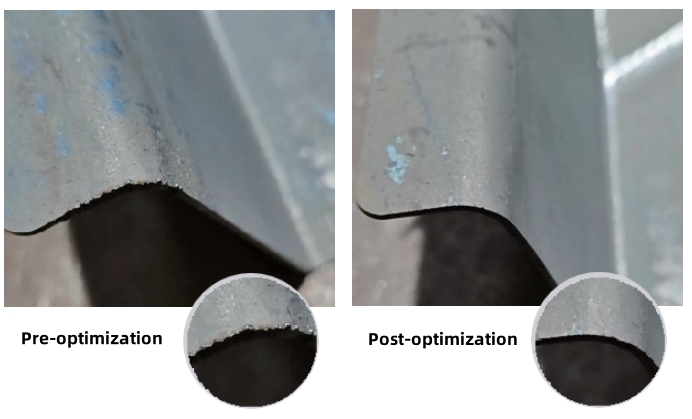

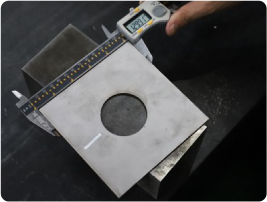

Excellent Edge Control Processes

•The machine offers a burr-free corner-cutting function, better controlling the corner cutting process.

•The laser power adjusts with speed changes, achieving almost burr-free corner cuts and superior edge quality.

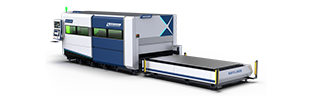

Extremely Fast

•The X-axis beam weight is reduced by 25%, with lightweight beams offering increased rigidity and strength.

•This improvement enhances the dynamic performance of moving parts.

•Sealing plates around the dust cover protect transmission parts from contamination, ensuring consistent and fast operation.

WD Series

Laser Source Power

X-axis itinerary

Y-axis itinerary

Z-axis itinerary

Single axis speed

accelaration

Location precision

Location precision

Rotation axis C axis

Oscillation axis A axis

CNC control system

Cutting head

Workbench

Workbench exchanging time

3000w ⁄ 4000w ⁄ 6000w (optional)

3000mm

1500mm

650mm

100m/min(X-axis can reach 120m/min)

1.0g(can reach1.2g)

±0.04mm

0.03mm

n*360°

±135°

Rexroth/Siemens

Han's latest cutting head

Rotation duel-station workbench

2.5s

3000w ⁄ 4000w ⁄ 6000w (optional)

3100mm

2200mm

650mm

100m/min(X-axis can reach 120m/min)

1.0g(can reach1.2g)

±0.04mm

0.03mm

n*360°

±135°

Rexroth/Siemens

Han's latest cutting head

Rotation duel-station workbench

4.5s

3000w ⁄ 4000w ⁄ 6000w (optional)

4000mm

2500mm

650mm

100m/min(X-axis can reach 120m/min)

1.0g(can reach1.2g)

±0.04mm

0.03mm

n*360°

±135°

Rexroth/Siemens

Han's latest cutting head

Rotation duel-station workbench

5.5s

contact us

LET’S TALK

LET’S TALK