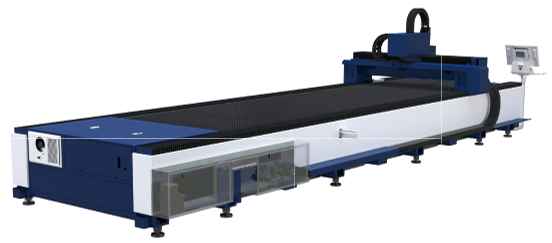

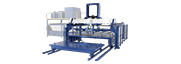

System Features

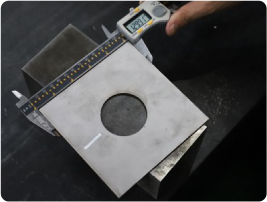

•Fully automatic load sheet metals, the max loading gauge reaches up to 40mm.

•The vacuum loading system links with production systems for task execution and management.

•The laser automation solution automates order-to-process workflows, including scheduling, material transfer, and machining.

Main Parts

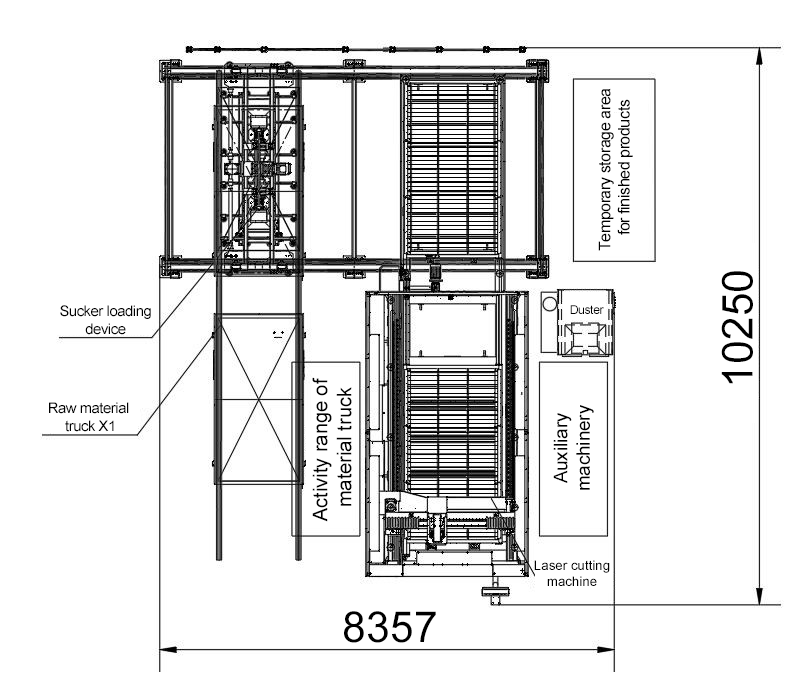

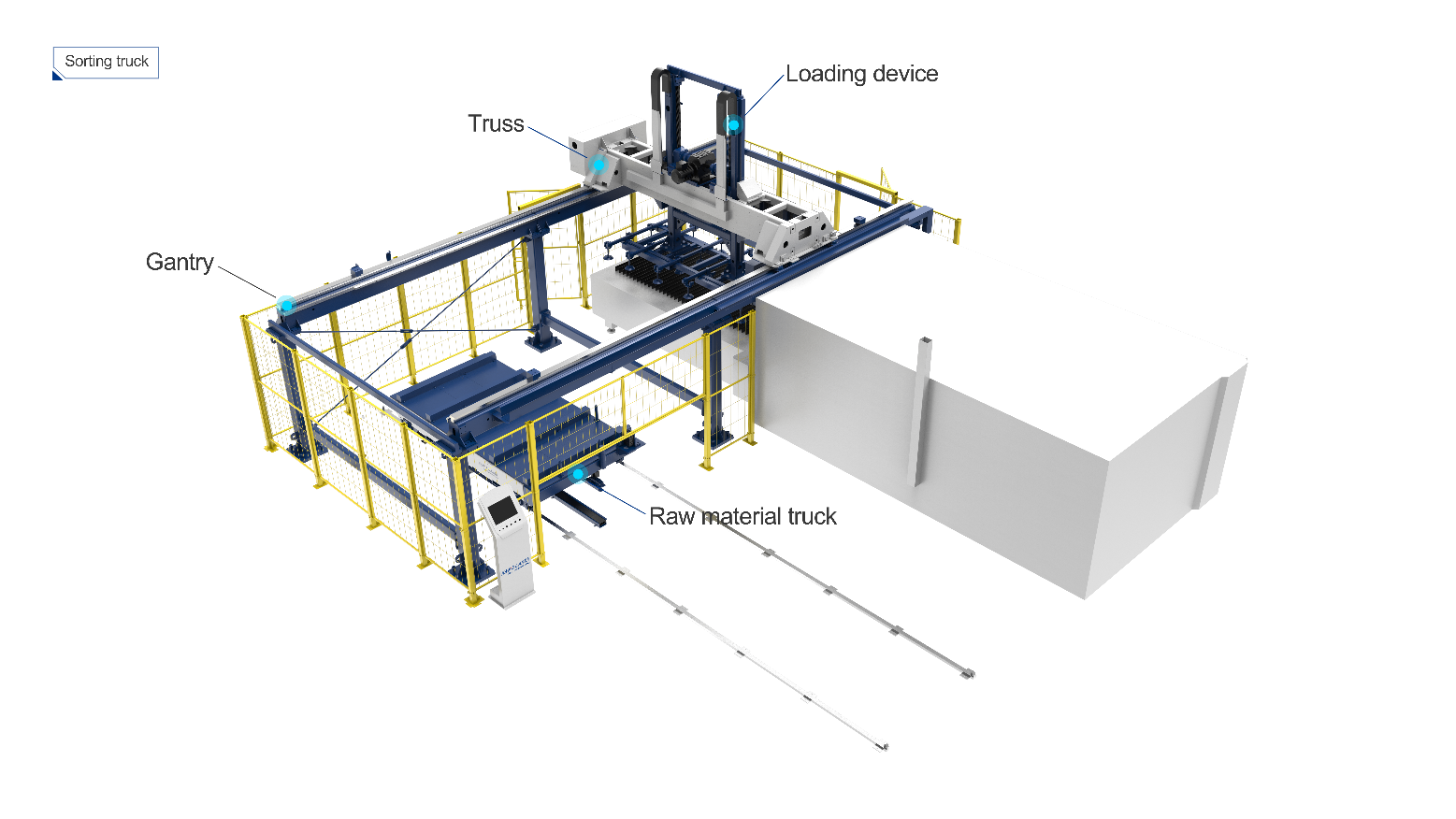

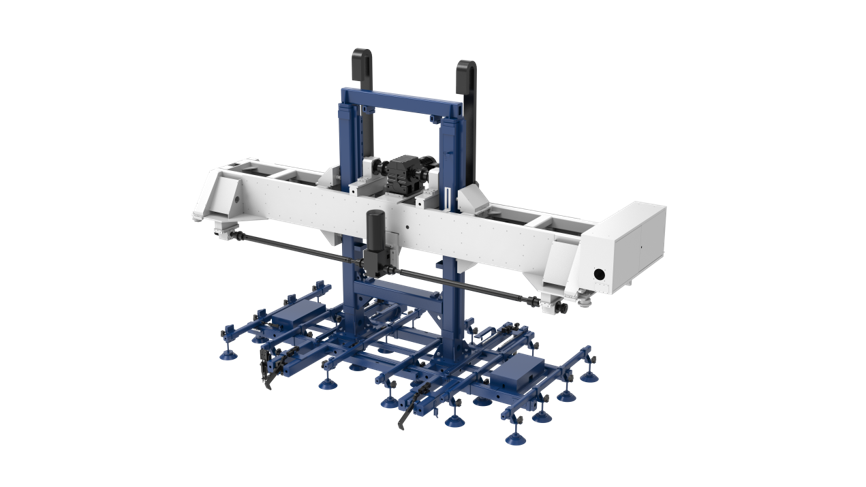

The single machine feeding machine mainly consists of a raw material truck, a gantry main frame, a truss, a feeding device, a sorting car combination, and a control system.

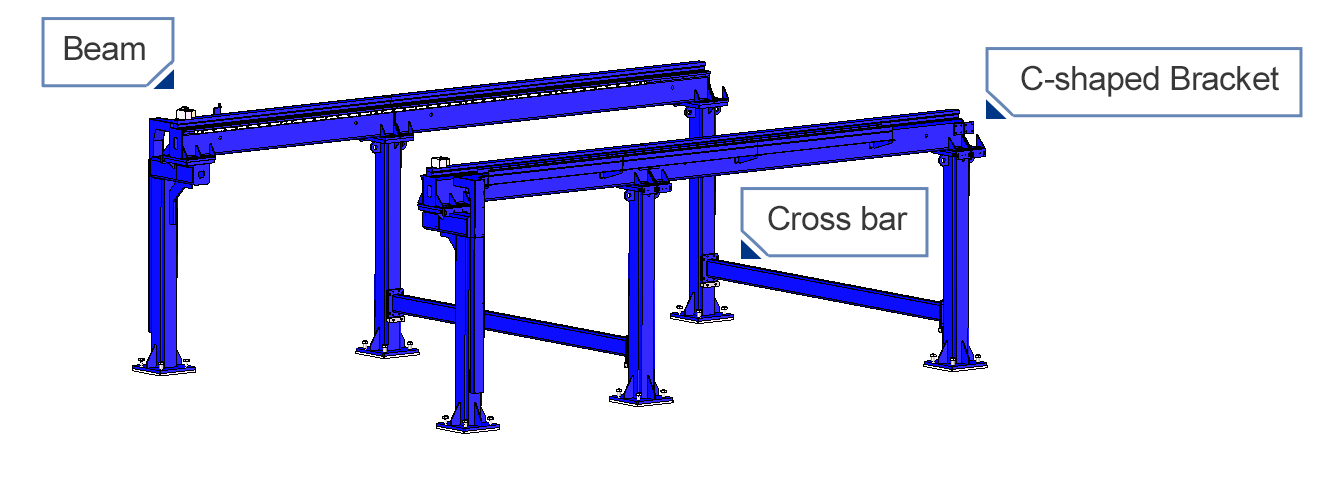

Gantry

All components of the gantry main frame are welded using profiles, and the process is welding → rough machining → vibration aging → precision machining, which effectively solves the stress caused by welding and processing and improves the stability of the gantry main frame. The bridge beam has a finely machined flat guide surface for the crossbeam to move on the gantry.

Truss

The truss part mainly consists of truss, transmission mechanism, guide device, bearings, and other parts. There are two servo motors , one driving the crossbeam to move forward and backward, and the other driving the material tray mechanism to move up and down. The truss moves horizontally on the gantry frame through cam bearings, as shown in the image.

Vacuum Suction Cup Feeding Device

The feeding mechanism comprises a welded main frame with guidance-transmission systems and vacuum suction cups. Each cup is independently controlled by solenoid valves, adapting to board dimensions for rapid, precise pickup. Safety features (travel limit sensors and anti-collision devices) ensure secure lifting operations.

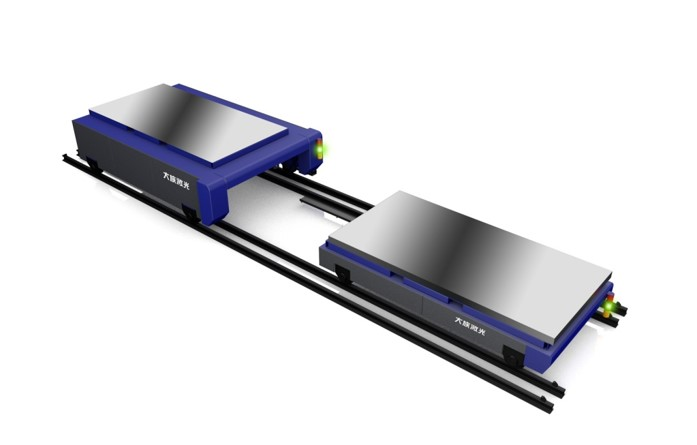

Raw Material Truck

The automatic assembly line system is equipped with one 4T raw material truck that can automatically move on the track, achieving the loading of materials.

contact us

LET’S TALK

LET’S TALK