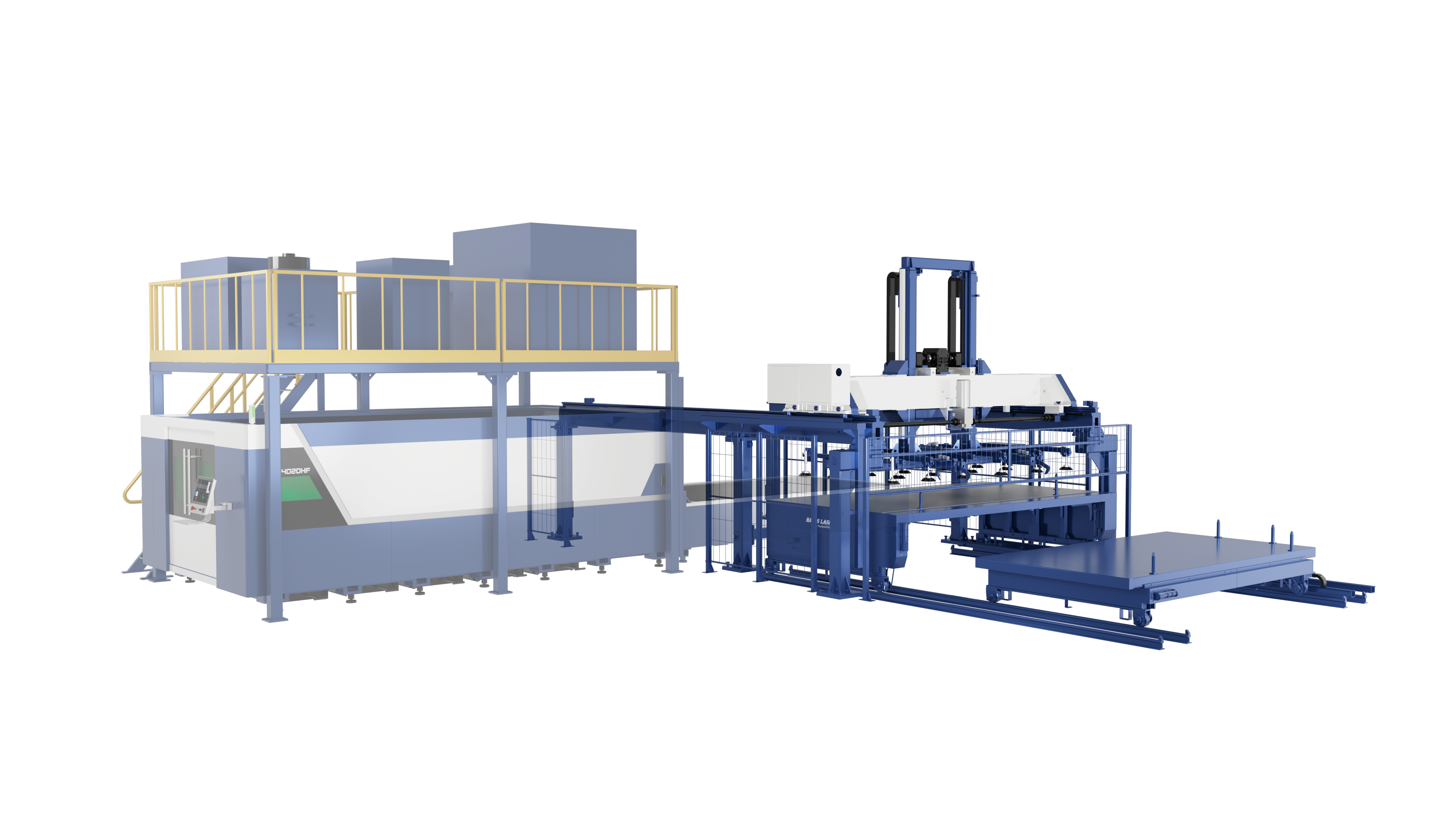

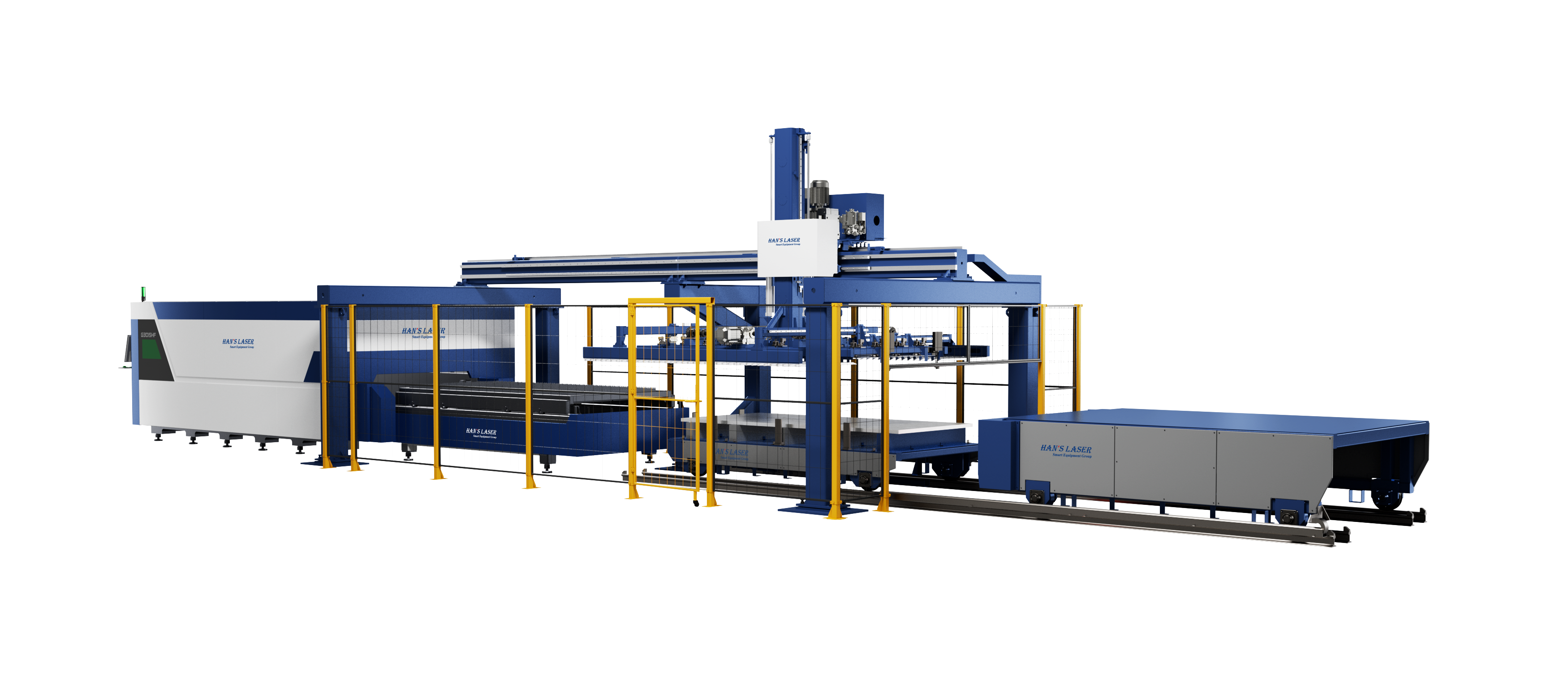

High-Efficiency Stable Fiber Laser Cutting System

•Very low operating cost, good stability and strong adaptability.

• Double-drive gantry structure, equipped with high-torque precision reducer, high precision, reasonable inertia and torque ratio, ensuring stable operation of the machine tool;

•The fiber laser adopts semiconductor modular and redundant design and works continuously 24 hours a day to meet the requirements of industrial continuous production.

•Fiber laser uses the rare element ytterbium as the luminescent material, with an electro-optical conversion rate of up to 35%, making it more low-carbon and economical.

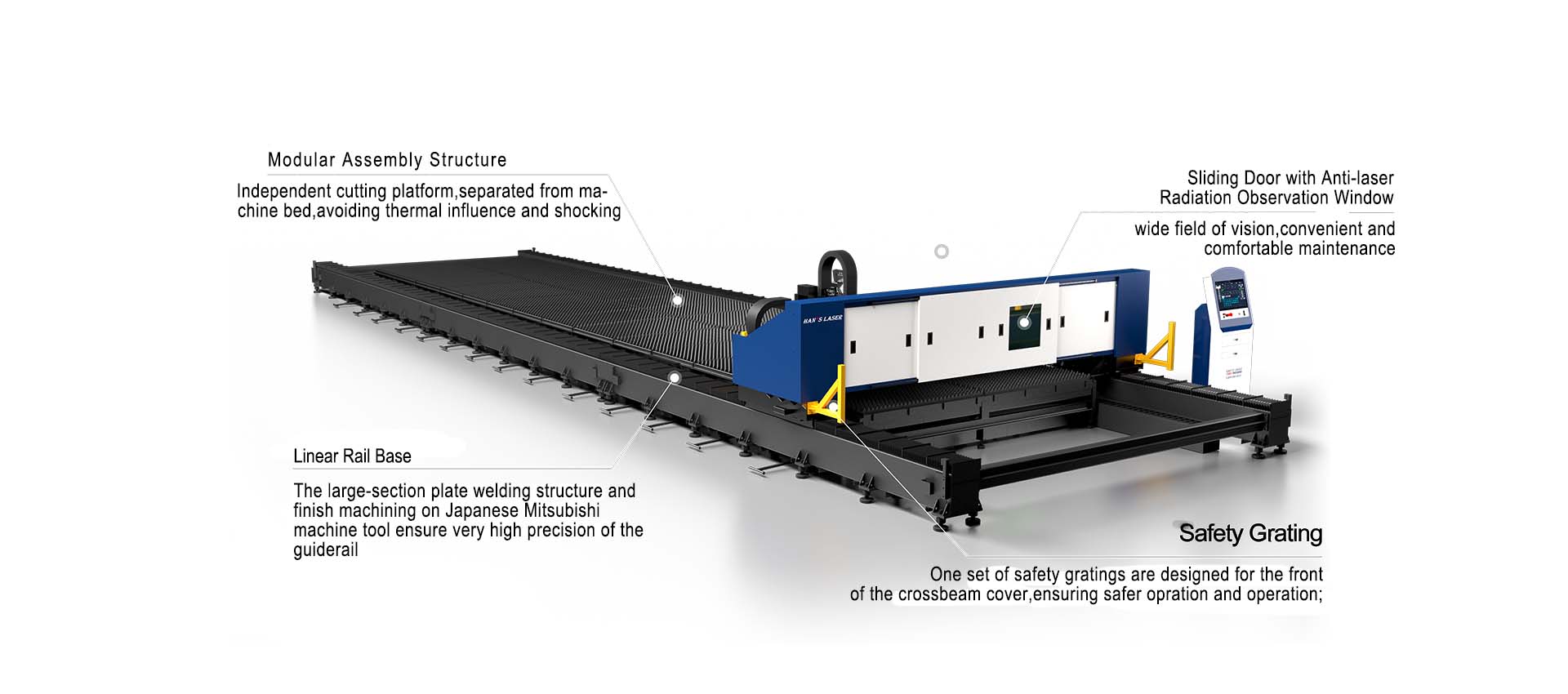

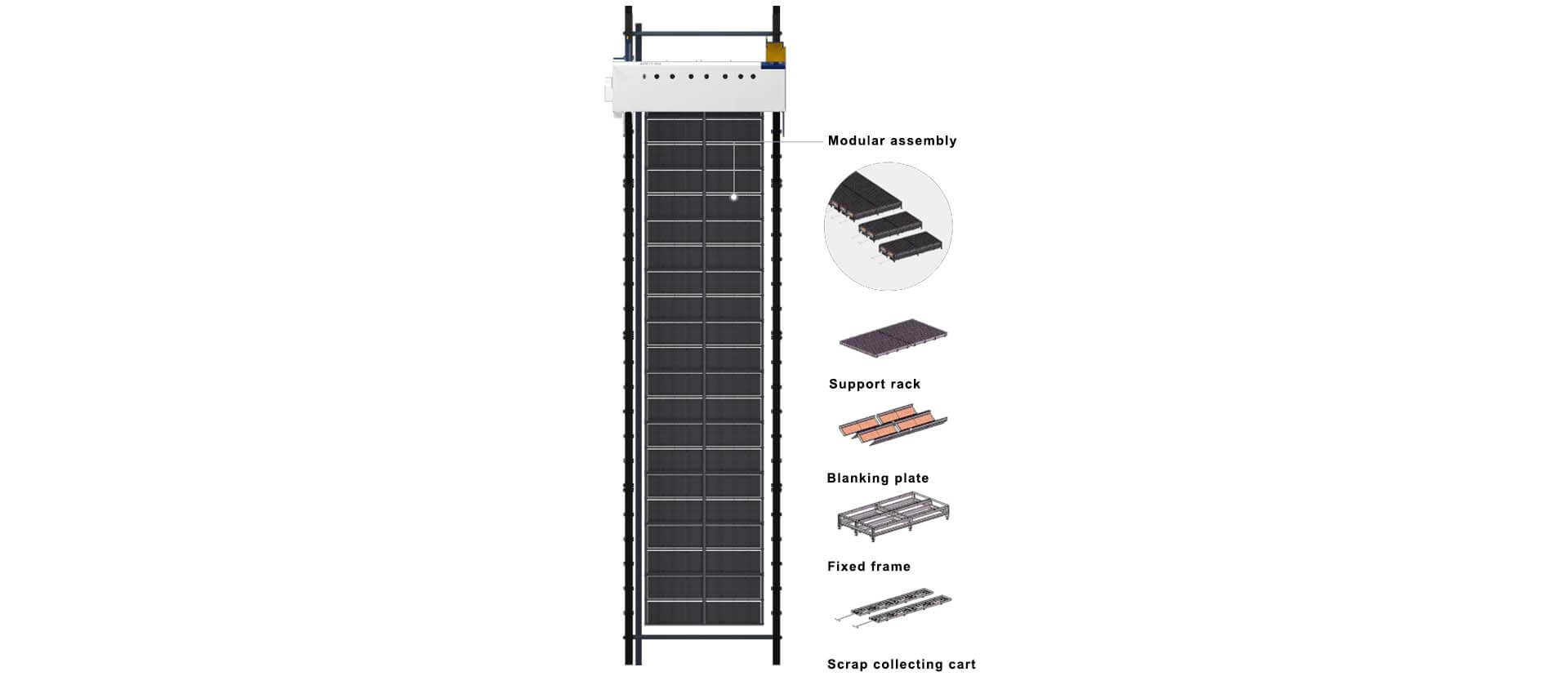

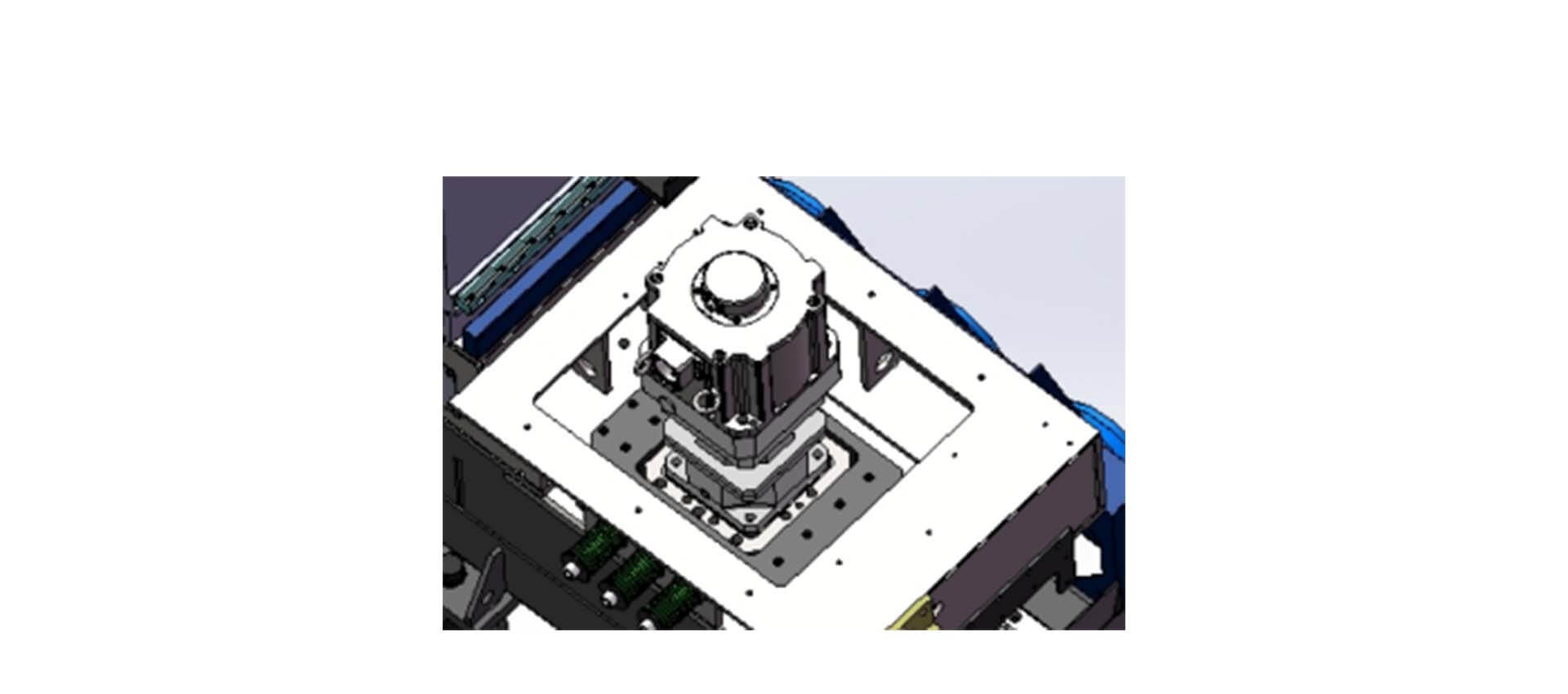

Modular Cutting Platform

Modular assembly, the worktable is fully separated from the machine bed, avoiding the thermal effects of high power laser cutting and avoiding shocks and vibrations during loading and unloading.

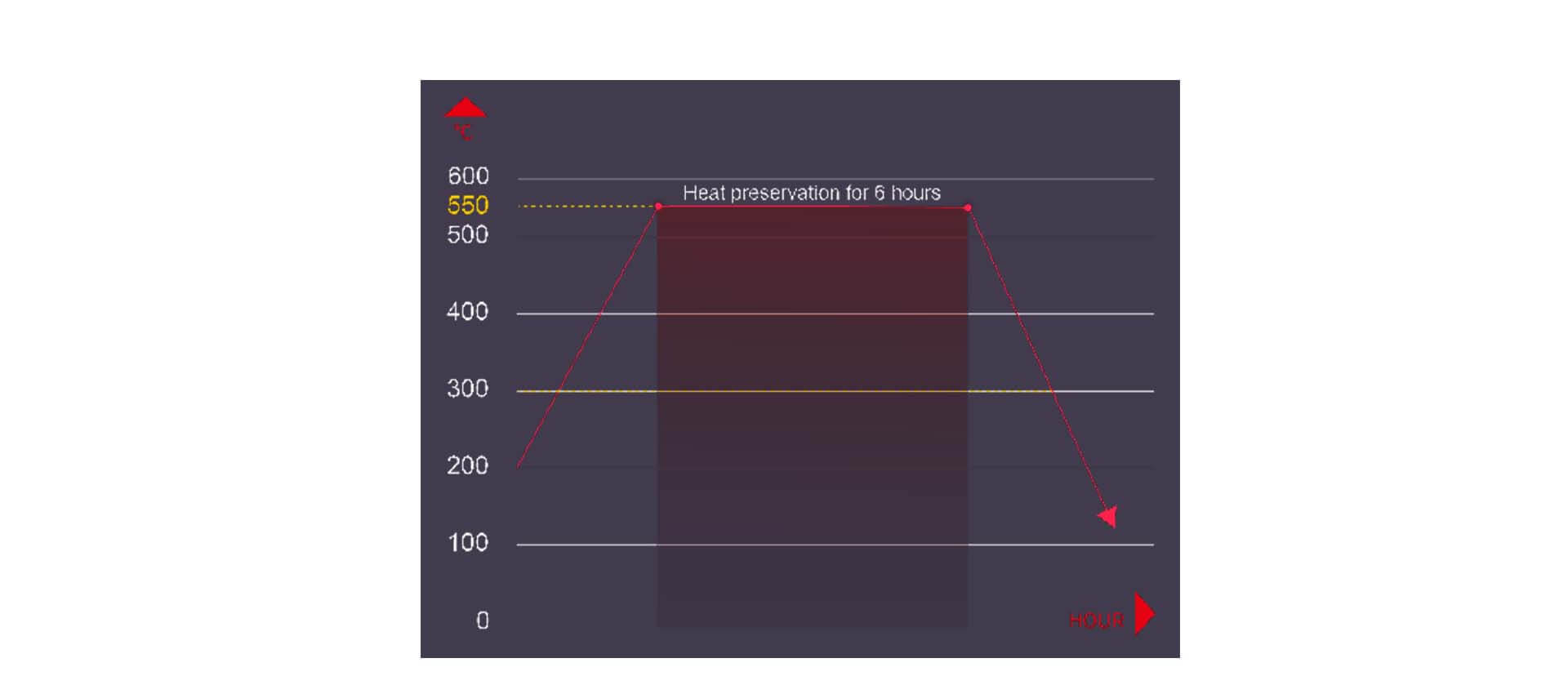

Machine Bed

•It adopts high-rigidity and large-section structure, and the steel plate is bent and inlaid and welded. After optimization by finite element analysis (FEA), the internal horizontal and vertical are inlaid with welded ribs;

•Using high-quality steel, annealed, rough machined, vibration aged, finished with Japanese Mitsubishi machine tool, and finally precision butted.

•Thus ultimately ensuring a very high precision.

Machine Tool Protection

Emergency stop button switches are installed in prominent positions on both sides of the crossbeam, and mechanical switches are used to control the travel of each axis at both ends. At the same time, buffer devices are used to effectively ensure the safety of machine tool movement.

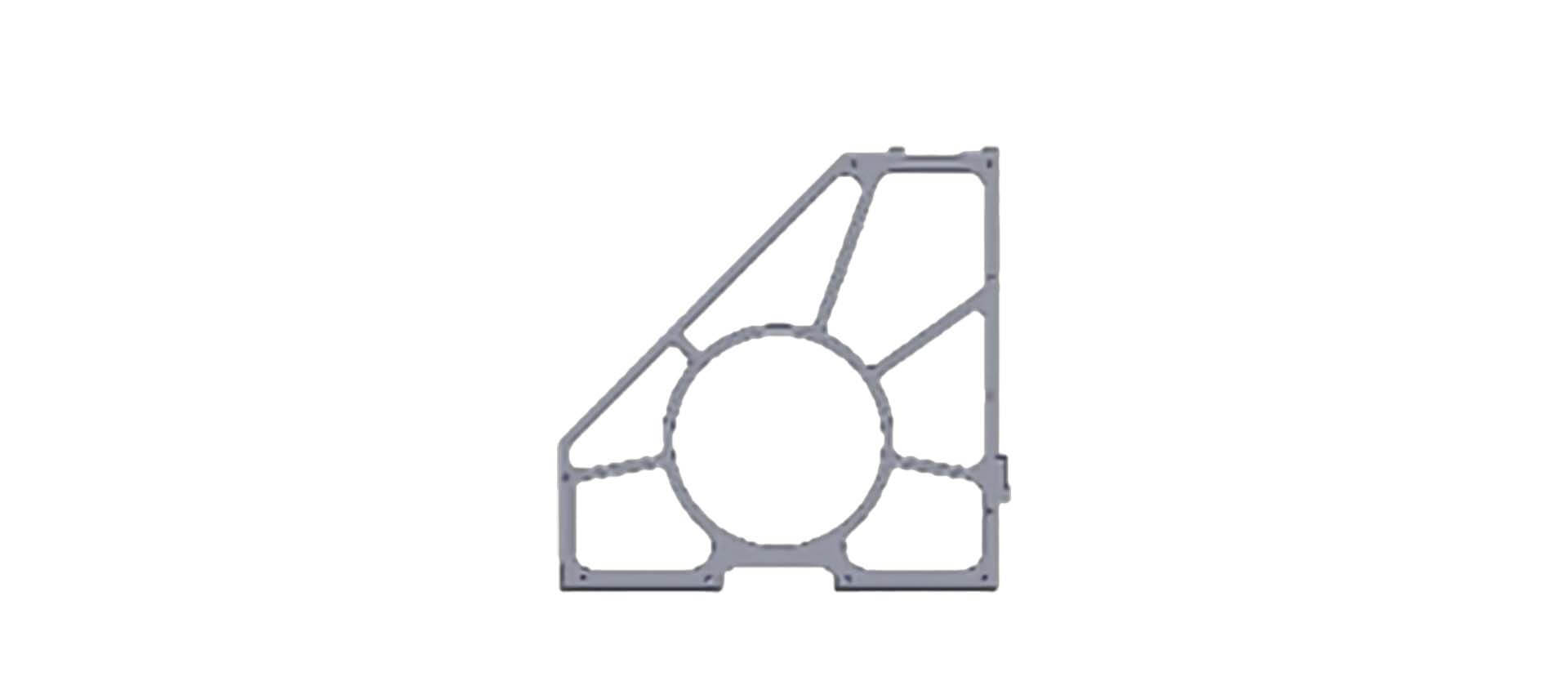

Extruded Aluminum Beams

•When the format width is below 4.5m, a high-rigidity extruded beam is adopted, optimized through finite element analysis. The inner cavity is designed to effectively disperse internal and external stress, resulting in a lighter structure and improved dynamic performance.

•The connection between the beam and pallet features an adaptive telescopic structure, ensuring long-term cutting stability across varying operating conditions.

Automatic Backlash Compensation

An automatic anti-backlash mechanism is integrated on both the left and right sides of the X-axis slide. This system ensures precise gear-rack engagement and resolves long-distance transmission accuracy challenges in large-format applications, enhancing positional stability across extended operational ranges.

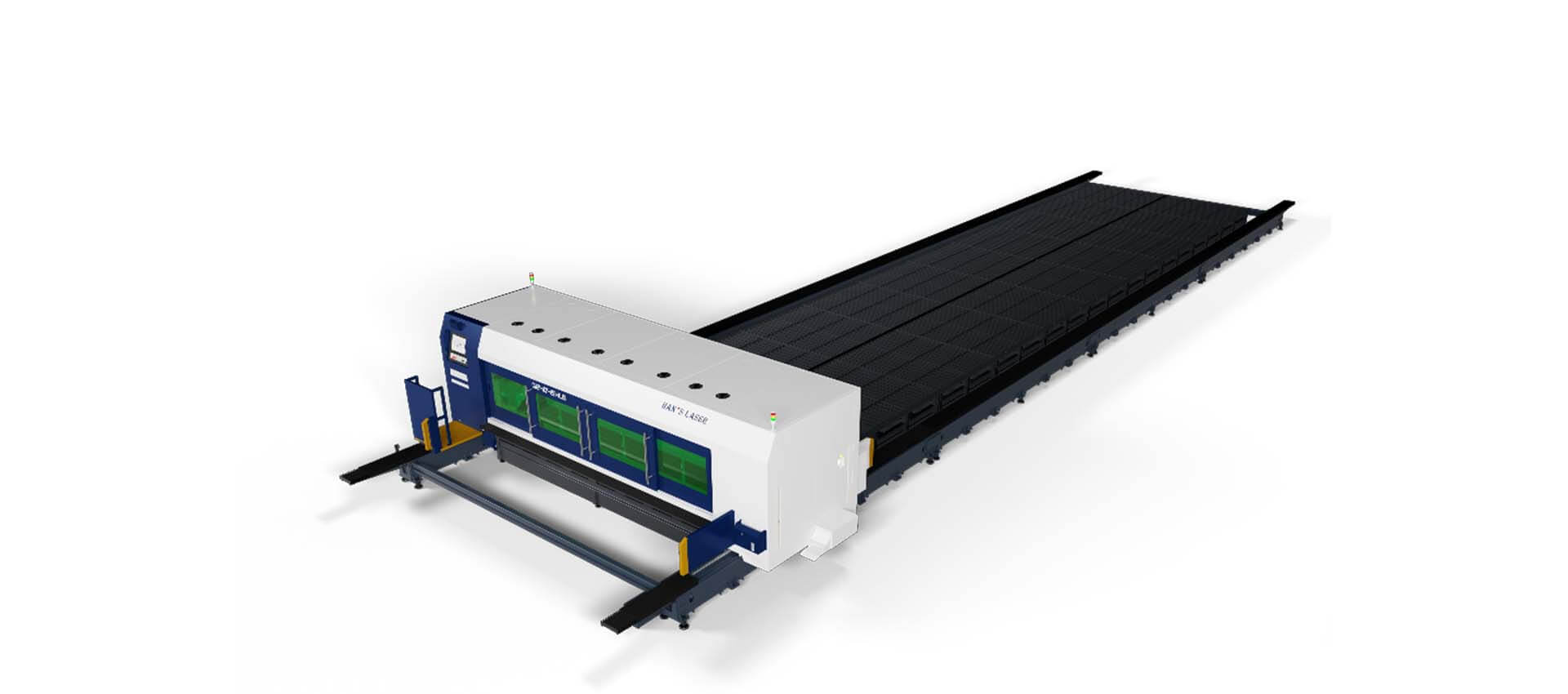

GIANT Series

Laser Power

Cutting Area (X × Y)

Positioning Accuracy

Repeat Positioning Accuracy

Max Cutting Speed

Acceleration

Machine Weight

Dimensions (L×W×H)

20kw/30KW

8000mm × 3000m

X axis:±0.07mm;Y axis:±0.05mm(full length)

X axis:0.05mm;Y axis:0.05mm(full length)

70m/min

0.7G

About 5.6 tons

About 12m × 4.9m × 2.1m

contact us

LET’S TALK

LET’S TALK