Cooling Method

All powers are water-cooled, which can extend the life of the laser and reduce the failure rate; the welding bead quality is more stable.

More Convenient to Move

Four universal wheels and four buckles at the bottom are oil-resistant, dirt-resistant, and impact-resistant, reliable and durable, easy to move, and can be fixed at any time.

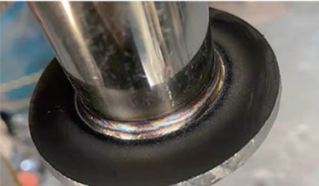

Professional Welding Gun

•All parameters are visible, multiple safety alarms are set to avoid problems in advance, facilitate troubleshooting and troubleshooting.

•Drawer-style protective/focusing mirrors enhance maintenance access, while integrated collimator-QBH modules allow on-site plug-and-play replacement.

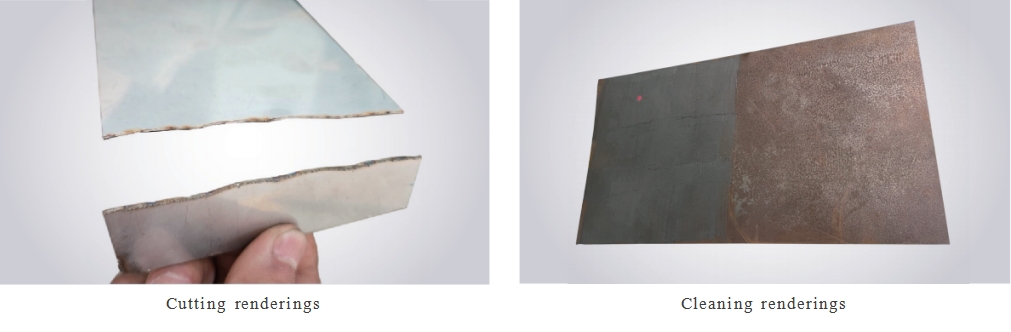

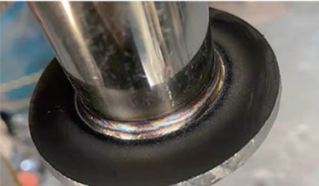

Simple Cutting and Rust Removal and Weld Bead Cleaning

•For thin plates (≤3mm), it can be achieved without changing the welding gun, just by changing the nozzle.

•Just change the nozzle to clean the plates with rust and paint on the surface up to 120mm width.

•Just change the nozzle to clean a 5mm wide weld bead.

Portable Wire Feeder

•New intelligent laser welding design ensures stable auto-wire feeding and premium weld quality.

•Multi-mode wire control (auto/manual feed/withdraw/draw/replenish) adapts flexibly to production demands.

•Supports welding wires with diameters of 0.8,1.0,1.2, 1.6,2.0mm

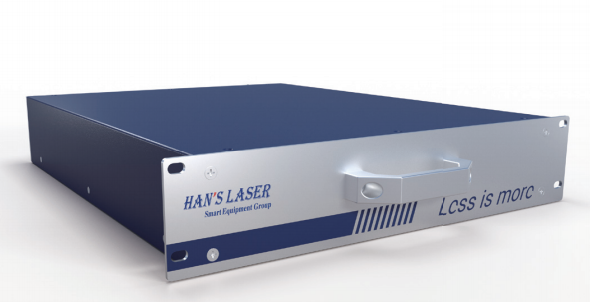

Highly Integrated Laser

•67% smaller & 50% lighter with fully sealed, dust/moisture-proof design for sustained operation.

•Mobile app enables real-time laser monitoring (power, configs, error codes) for swift maintenance.

•1500/2000W: 25μm (10m); 3000W: 50μm (12m). Ultra-long fibers suit large workpieces & diverse conditions.

DZW Series

Max. sheet Thickness

Max Power of Whole Machine

Laser Wavelength

Welding Speed

Welding Crack

Power Supply

Ambient Temperature

Ambient Humidity

Machine Weight

Size(W*D*H)

Stainless steel: 0.6-4.0mm/Carbon steel: 0.6-5.0mm/Aluminium: 0.6-3.0mm

8.5kW

1064±10nm

Without filler wire welding,≤0.3

AC220V,50Hz

10℃~40℃

<70%(No condensation)

102kg

L1080×W580×H780 mm

Stainless steel: 0.6-5.0mm/Carbon steel: 0.6-6.0mm/Aluminium: 0.6-4.0mm

11kW

1064±10nm

0~600cm/min (Different due to model, plate thickness, workpiece)

With filler wire welding,≤0.5

AC220V,50Hz

10℃~40℃

<70%(No condensation)

111kg

L1080×W580×H780 mm

Stainless steel: 0.6-8.0mm/Carbon steel: 0.6-8.0mm/Aluminium: 0.6-6.0mm

11kW

1064±10nm

AC380V,50Hz

10℃~40℃

<70%(No condensation)

145kg

L1100×W580×H900 mm

contact us

LET’S TALK

LET’S TALK