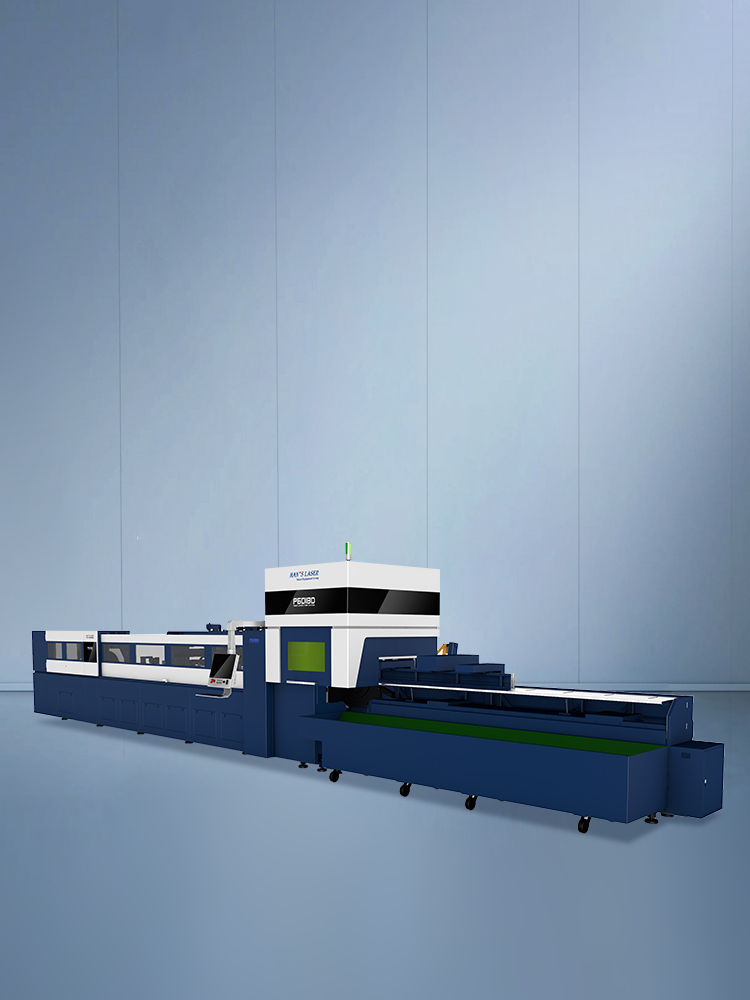

Laser Tube Cutting Machine

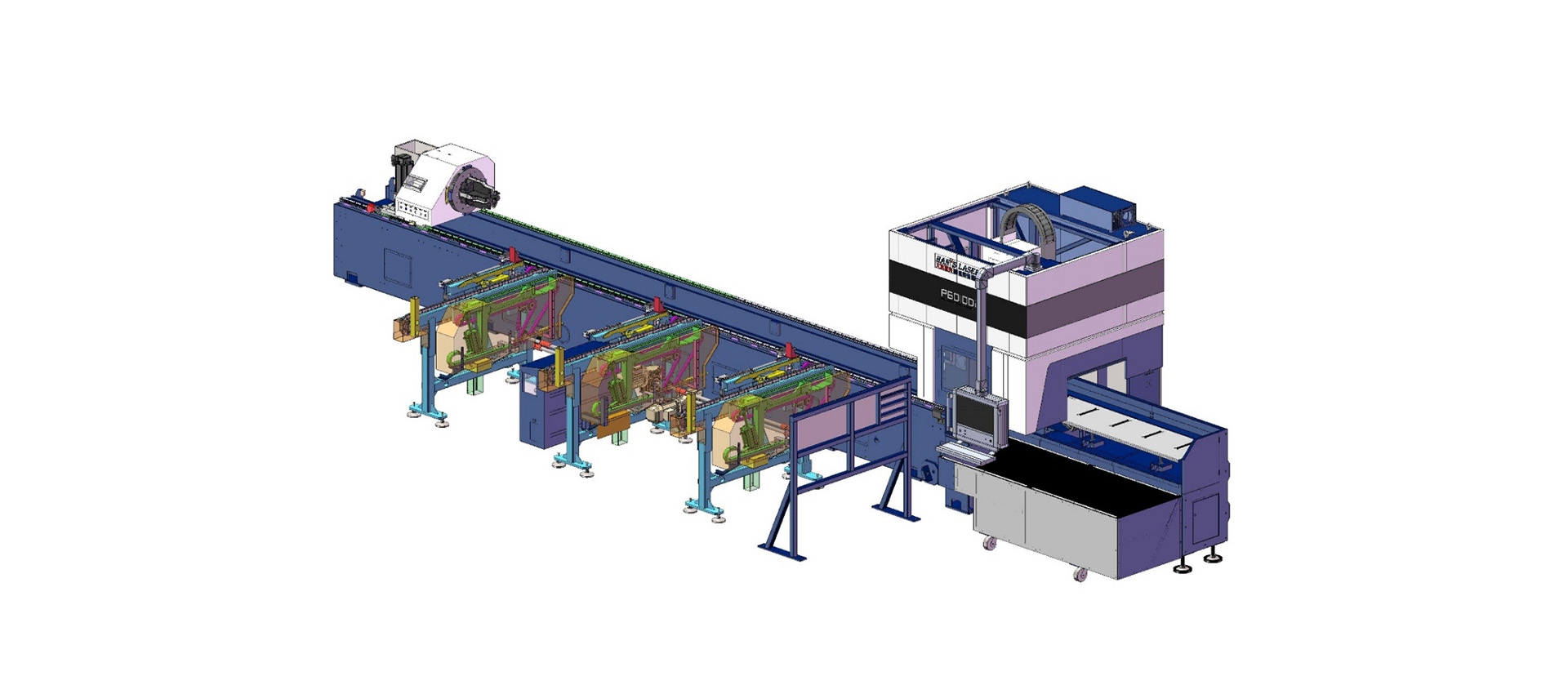

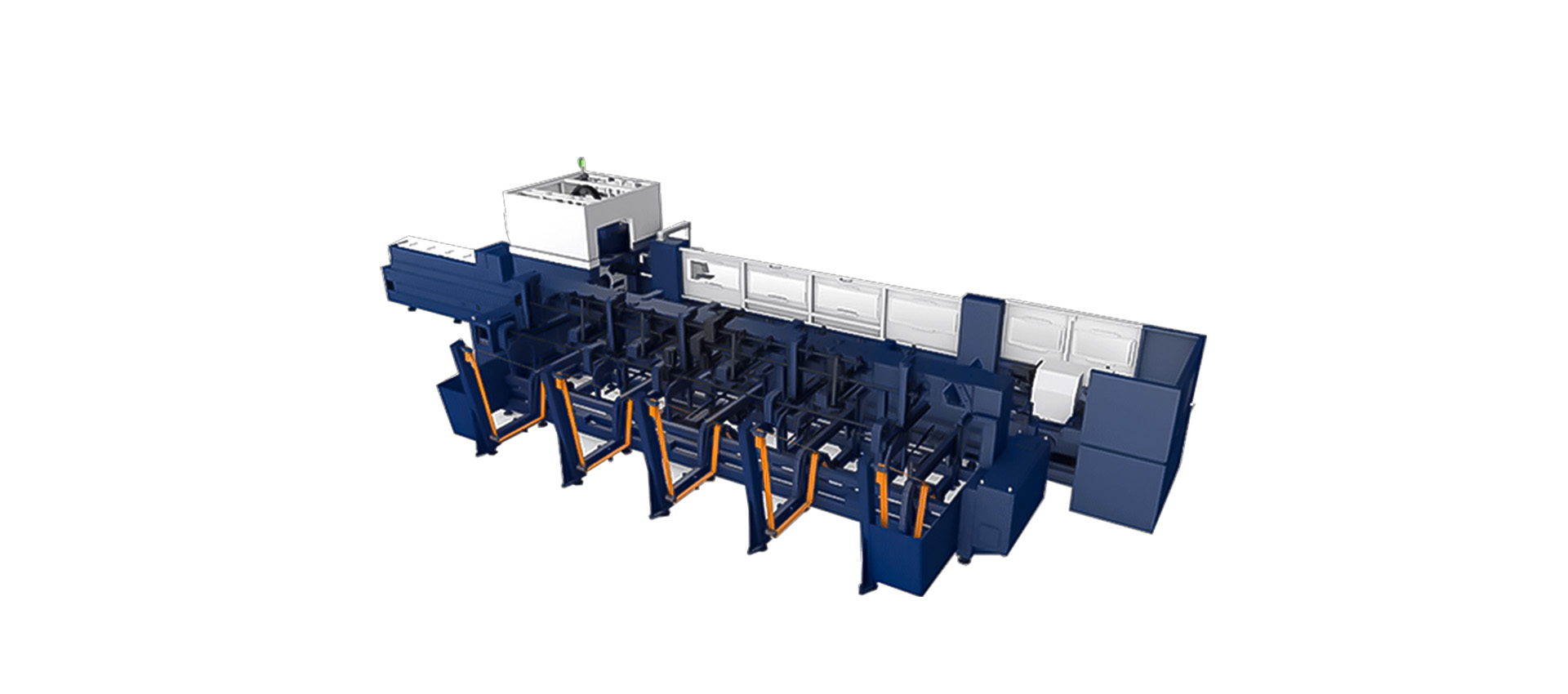

● The PD series laser tube cutting machine is It is a precision CNC automatic laser pipe cutting machine integrating laser cutting, precision machinery, numerical control technology, etc.

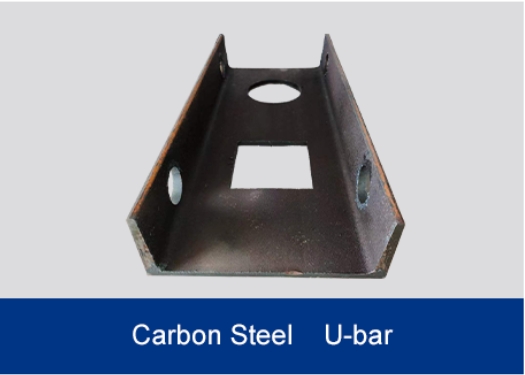

● It’s mainly used for metal tubes cutting such as mild steel, stainless steel, aluminum alloy tube (square, round, oval tubes) and others tubes (please indicate if there are oval tubes).

● It is the preferred cutting machine in the metal tube processing industry, with the characteristics of professionalism, high speed, high precision, high efficiency and high cost performance.

Why Choose PD-Series

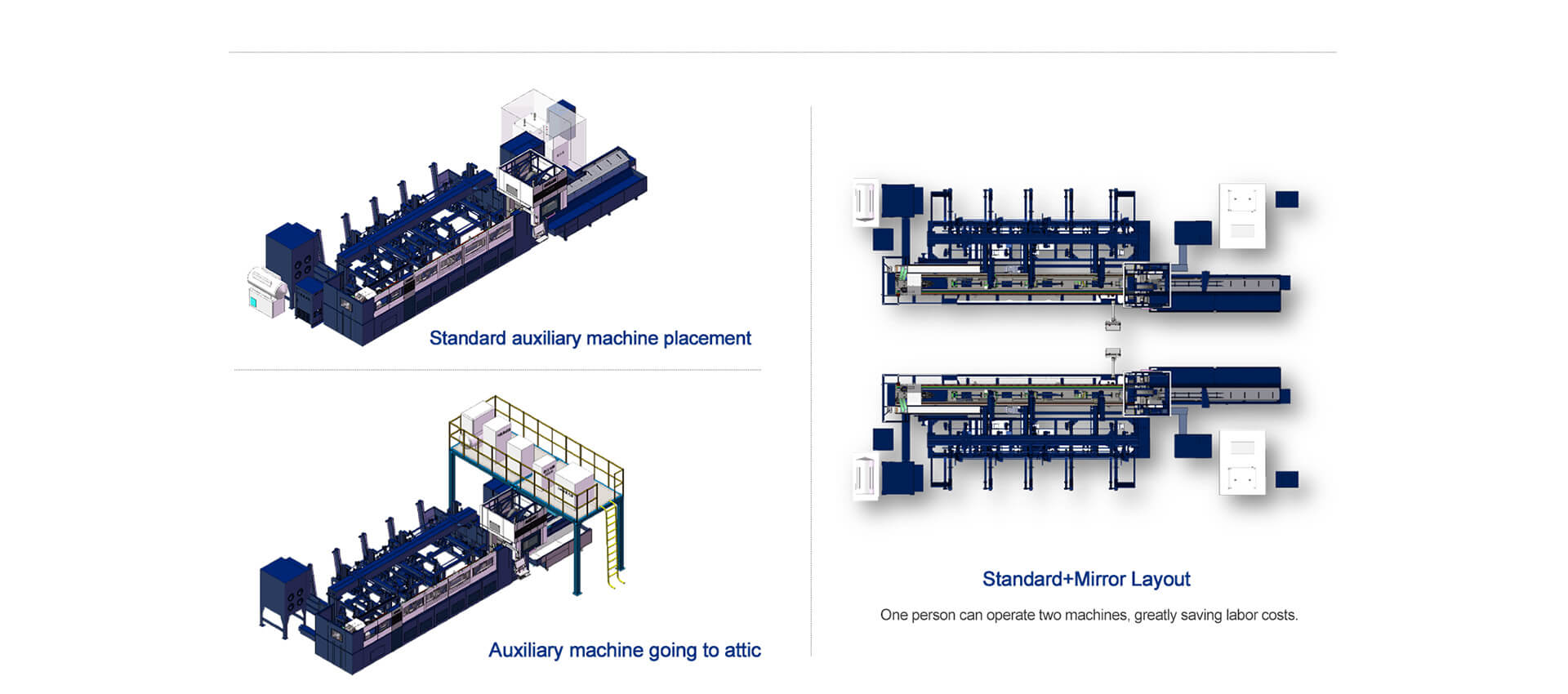

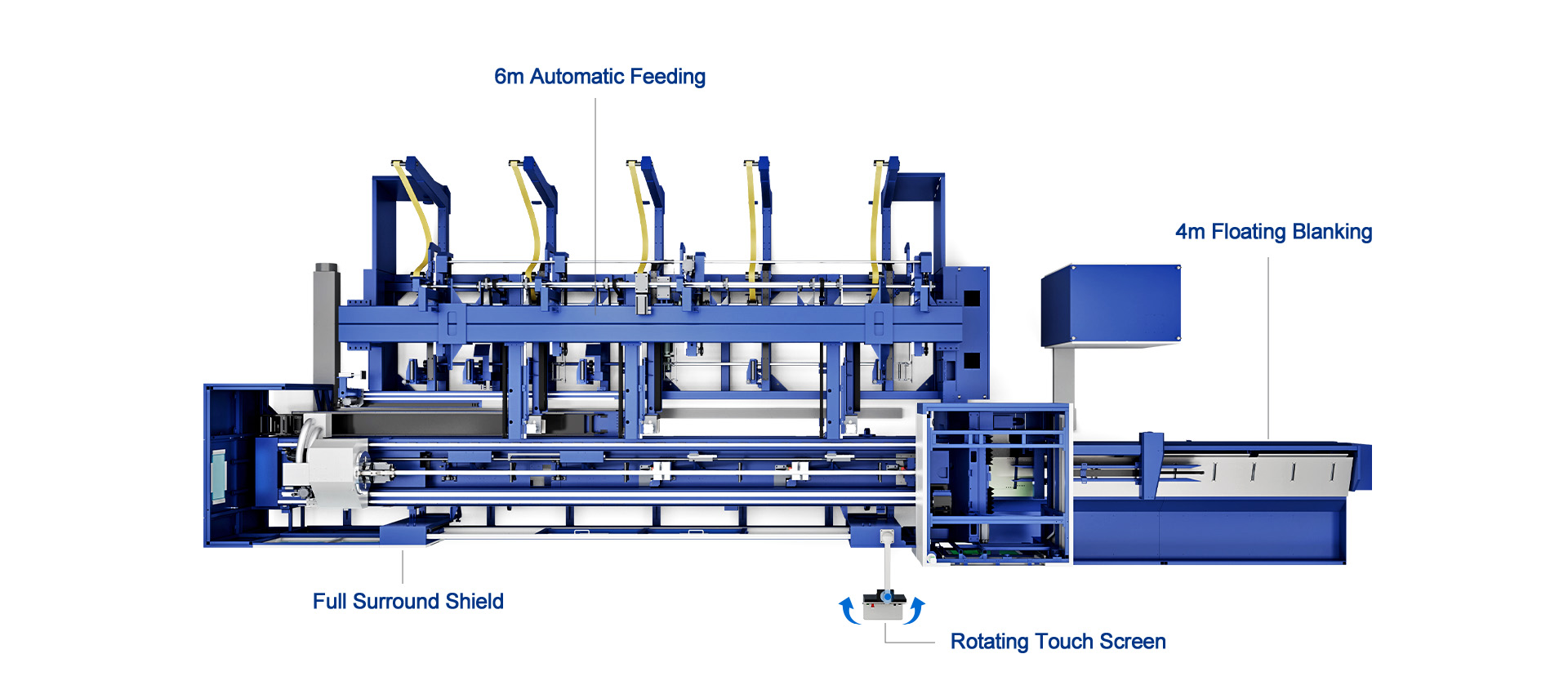

The machine adopts a horizontal structure, gears and racks, and high-precision linear guide rails, with smooth transmission and high accuracy. It is equipped with fully automatic loading and unloading devices, greatly improving the production efficiency of the machine tool.

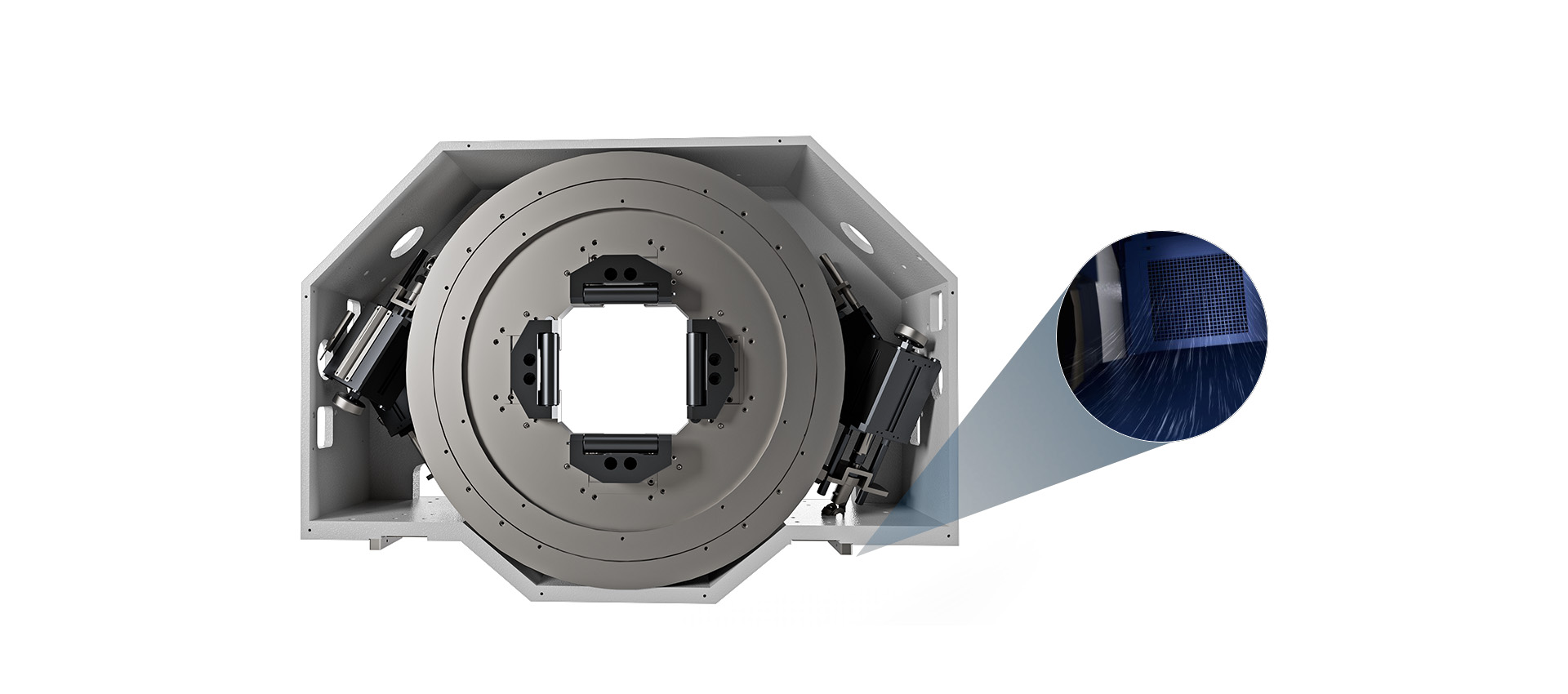

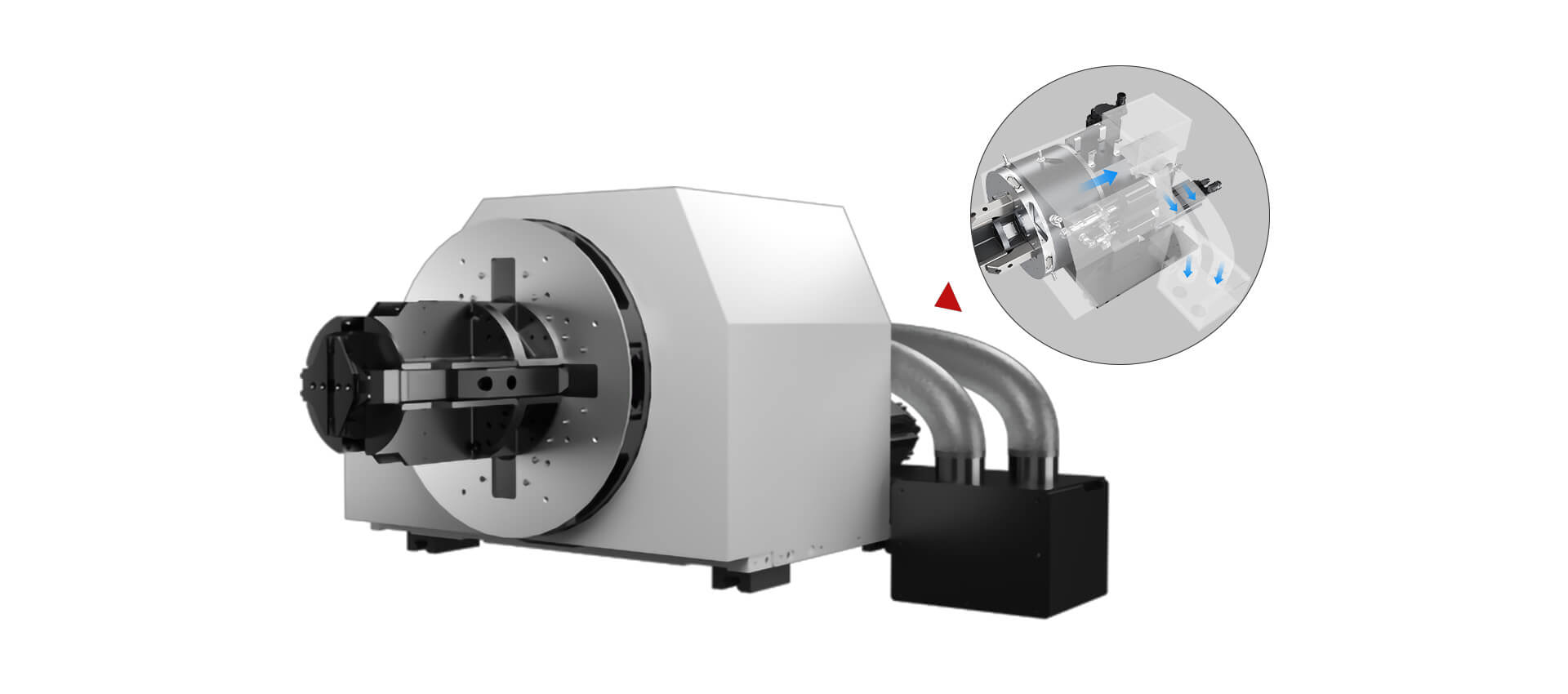

Clamping System

• High safety when gas is cut off and pressure is maintained

• Mechanical transmission structure, high safety factor in component design, capable of stable 24-hour continuous production

• The gripper has a short stroke and high repeatability accuracy

• Digital monitoring, real-time identification of clamped pipe size

Rear chuck

• Adopting an exhaust structure with good internal sealing.

• The front and rear air exhausters are set to remove the high-temperature gas in the tube, avoid the impact of thermal deformation on the accuracy, effectively remove the cutting dust and improve the working environment.

• The chuck is designed with a recognizable clamping pipe size structure and corresponding sensors.

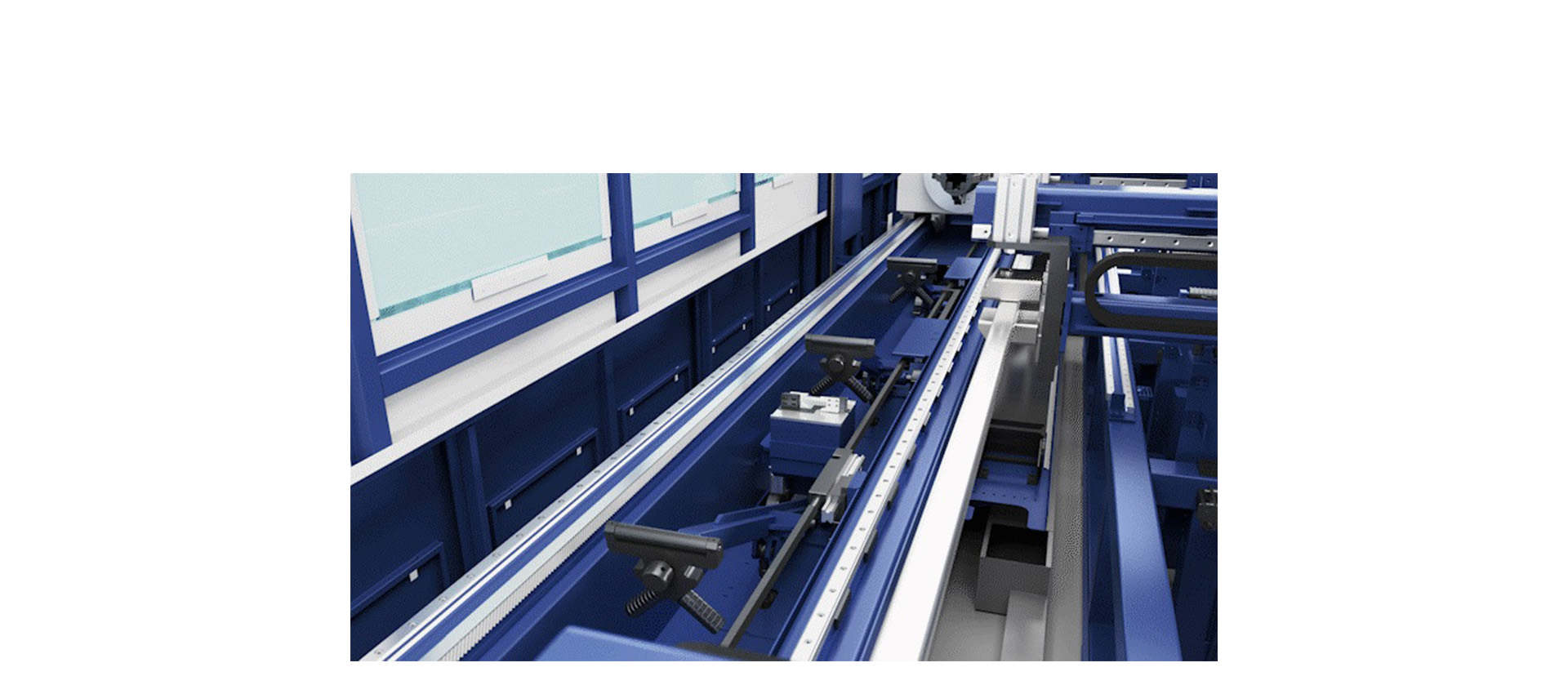

Floating Support

•The X-axis adopts gear and rack transmission and linear guide rail guidance, ensuring reliable operation;

•The servo auxiliary support device floats up and down to ensure effective support, prevent the pipe from sagging, and improve processing accuracy.

Adjustable Console

The console can be adjusted in real time according to operator heights.Multi angle rotation operation, convenient for observation while operating, and suitable for various operation conditions.

PD Series

Machine Type

Laser Source Power

Max. Machining Range

Max. speed (A,B axis)

X/Y axis rapid traverse speed

Max. load capacity

Max. material length

P6010D/P6018D/P8018D/P10018D

1000w ⁄ 2000w ⁄ 3000w ⁄ 4000w (Customizable)

Φ 20-180 mm Φ 20-180 mm (Optional:Φ 20-110 mm Φ 20-110 mm)

120r/min (Optional: 150r/min)

120m/min

260kg

12200mm

contact us

LET’S TALK

LET’S TALK