Main Parts

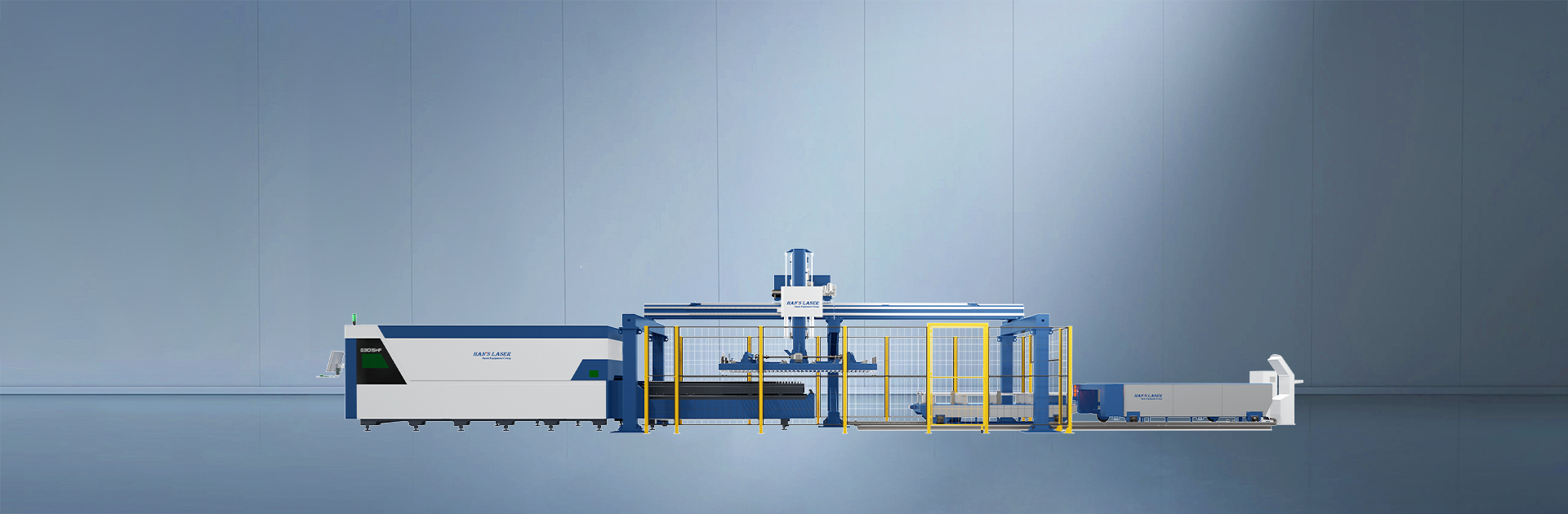

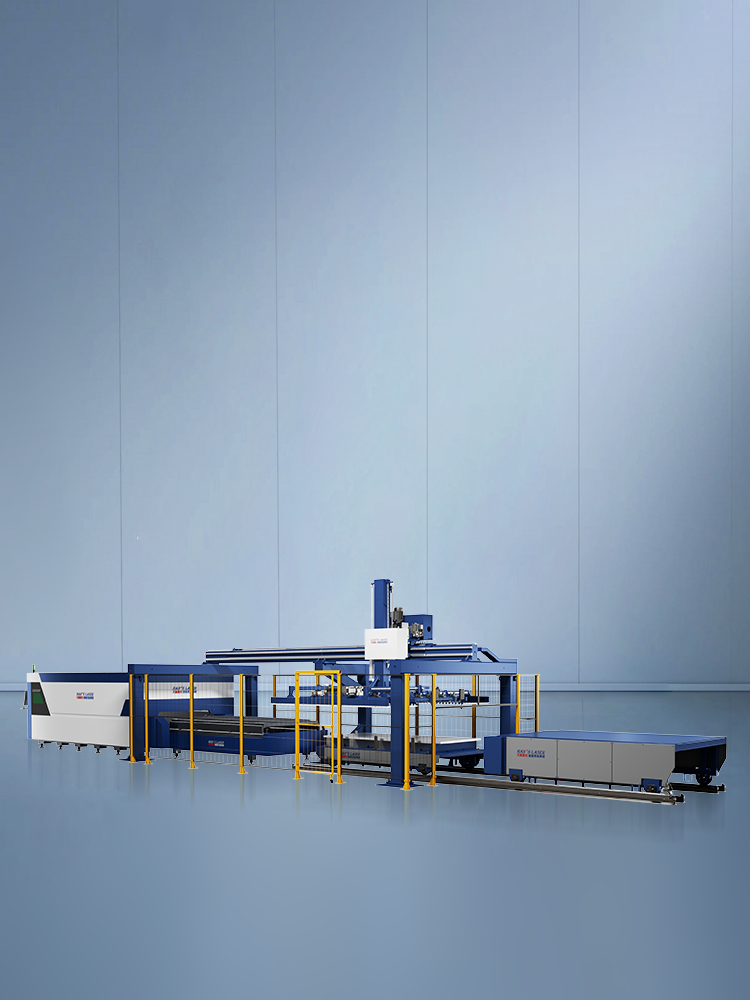

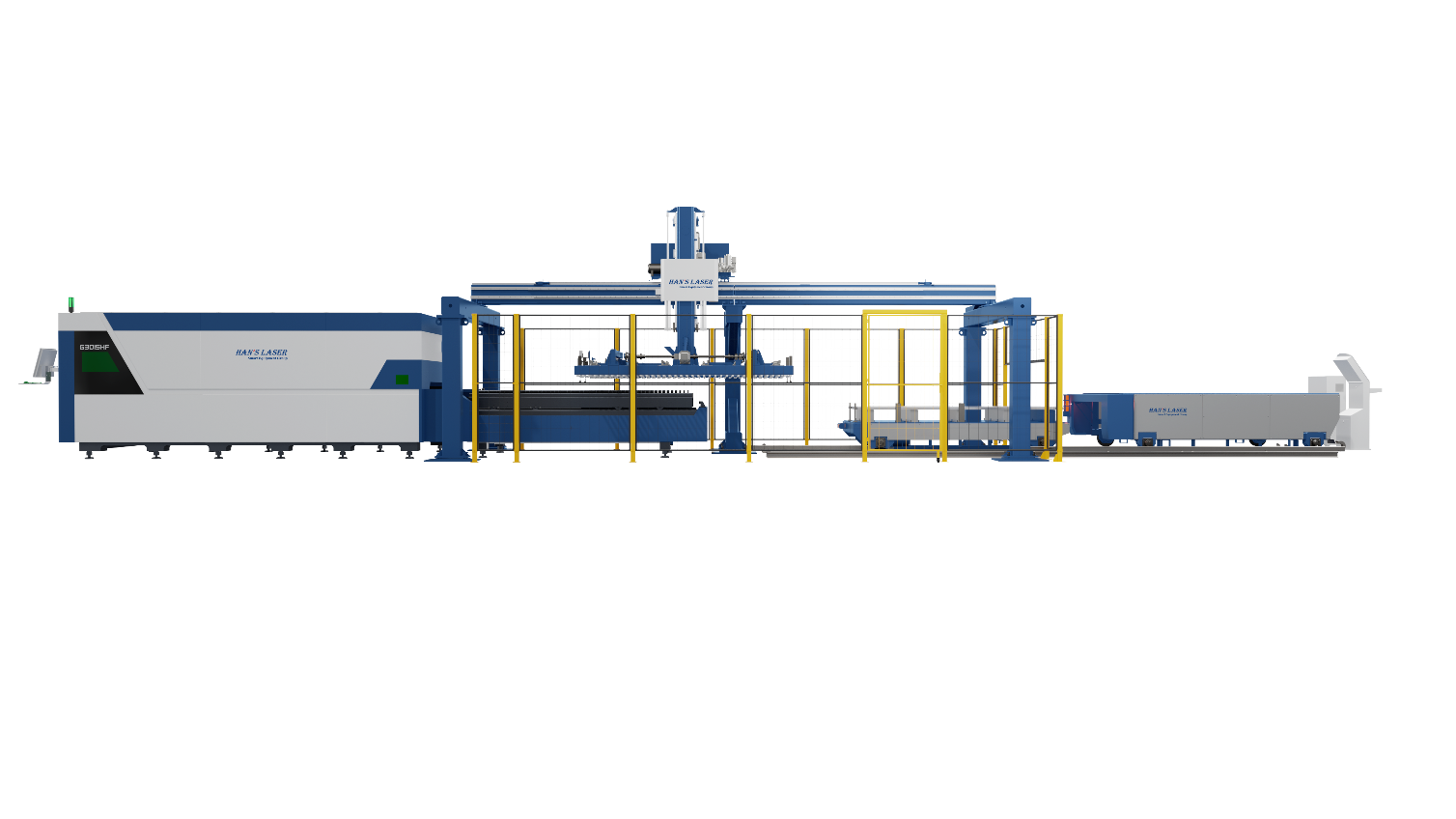

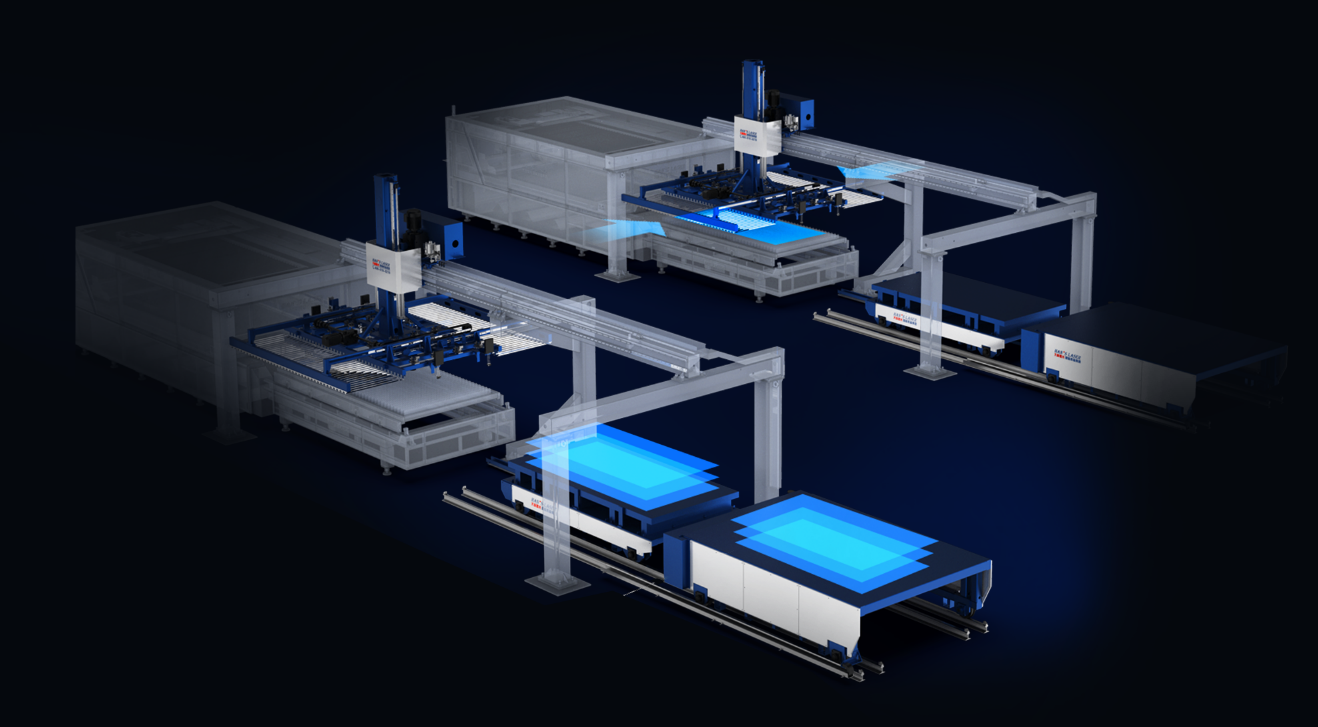

The automated loading and unloading system is mainly composed of C-shaped bracket assembly line, loading and unloading integrated device, high and low electronic carts and control system.

The system consists of the following components:

•C-shaped bracket;

•Vacuum suction cup loading device;

•Span beam traveling line;

•Fork unloading device.

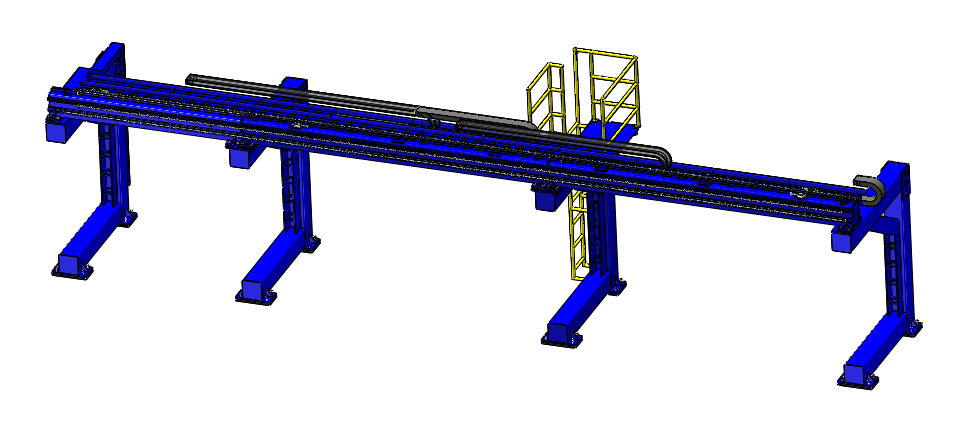

C-shaped Bracket Assembly Line

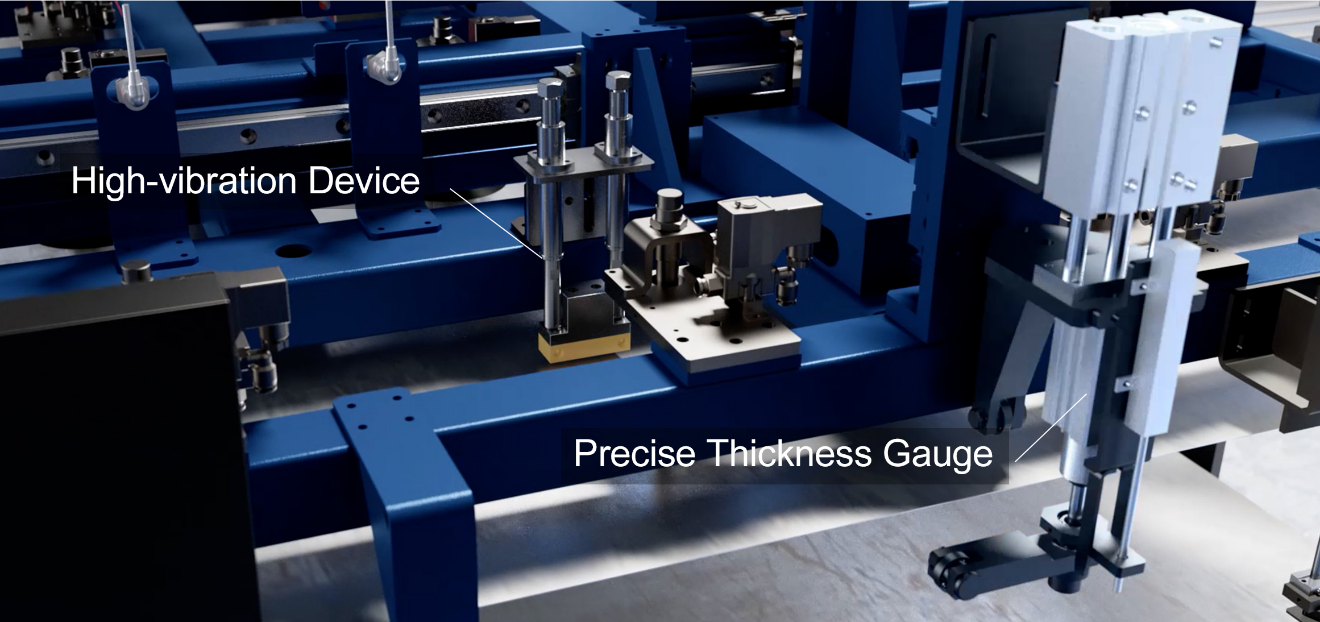

The main machining parts such as the span beam of the C-shaped bracket are welded by profiles. The process is as follows: Welding → Rough machining → Vibratory stress relief → Refined machining, which can better relieve the stress caused by welding and processing and improve the stability of the C-shaped bracket assembly line.

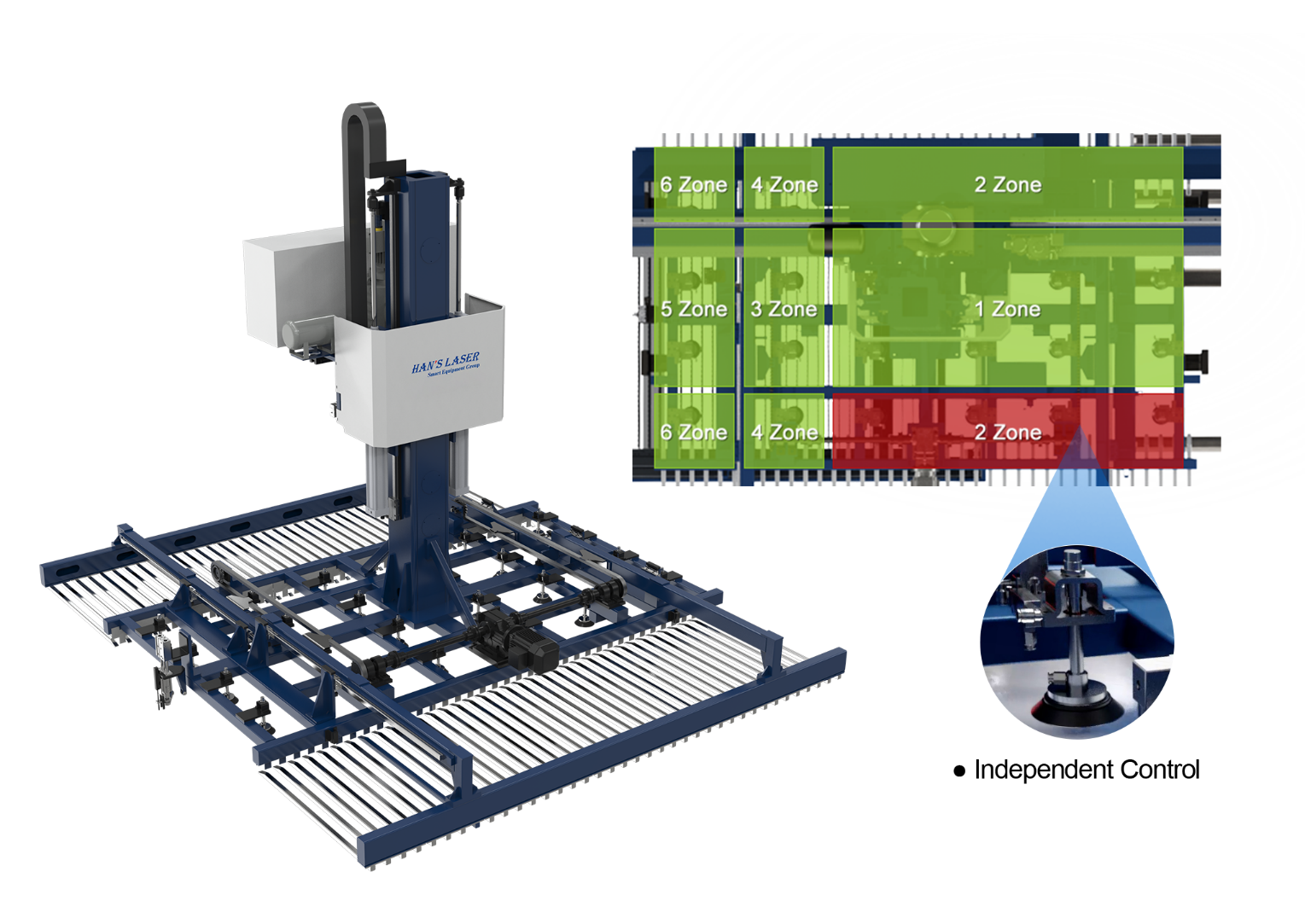

Loading and Unloading Integrated Device

The integrated loading/unloading mechanism features a welded frame with guidance-transmission systems, supporting vacuum suction cups (individually solenoid-controlled for adaptive sheet gripping) and a comb-shaped fork. The fork lifts finished/waste materials from worktable gaps via horizontal insertion, transferring them to sorting carts, while the system enables vertical/horizontal movement for precise sheet handling.

•Independent control for each suction cup, flexible and compatible with multiple format sheet metals.

•Equipped with dual functions of automatic loading and unloading, it runs quickly and accurately. It uses vacuum suction cups to absorb raw materials and plates, and has a sparse fork for unloading, ensuring high safety.

Effective Layering

Sensitive thickness measurement, precise layering, ensuring single sheet production and preventing incorrect cutting of plates during the production process.

Seamless Transition

Continuous loading and unloading significantly boost productivity by eliminating unexpected manual operations.

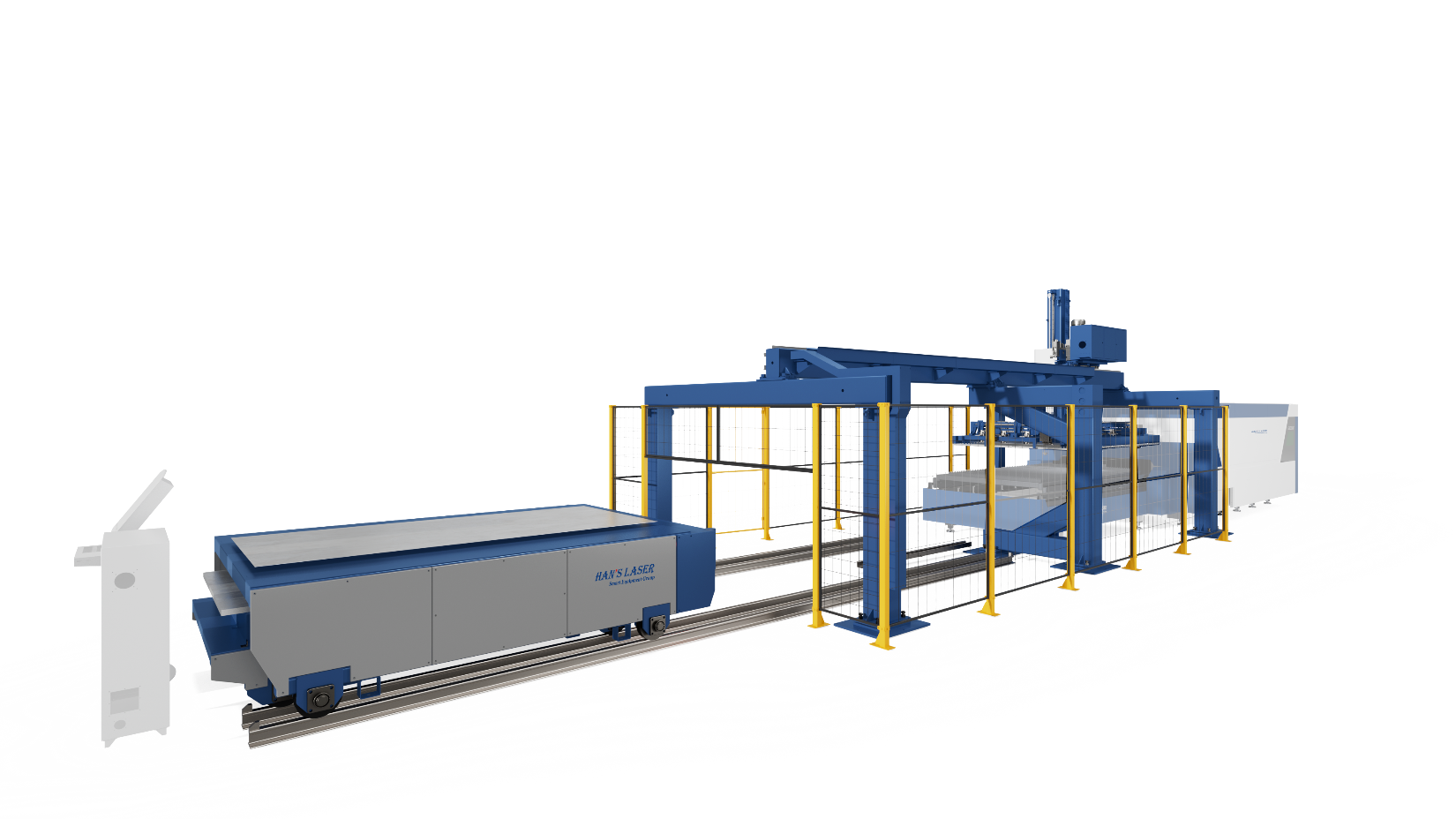

Safety Fence

Equipped with safety interlock switches, the equipment operates automatically in the area, and adopts safety guardrails without deadangle protection to prevent personnel from entering and ensure the safe operation of the system.

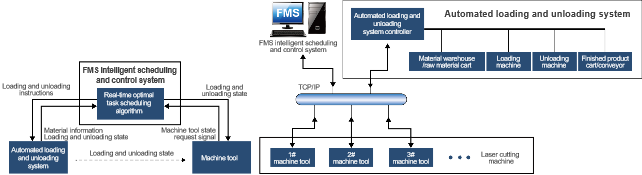

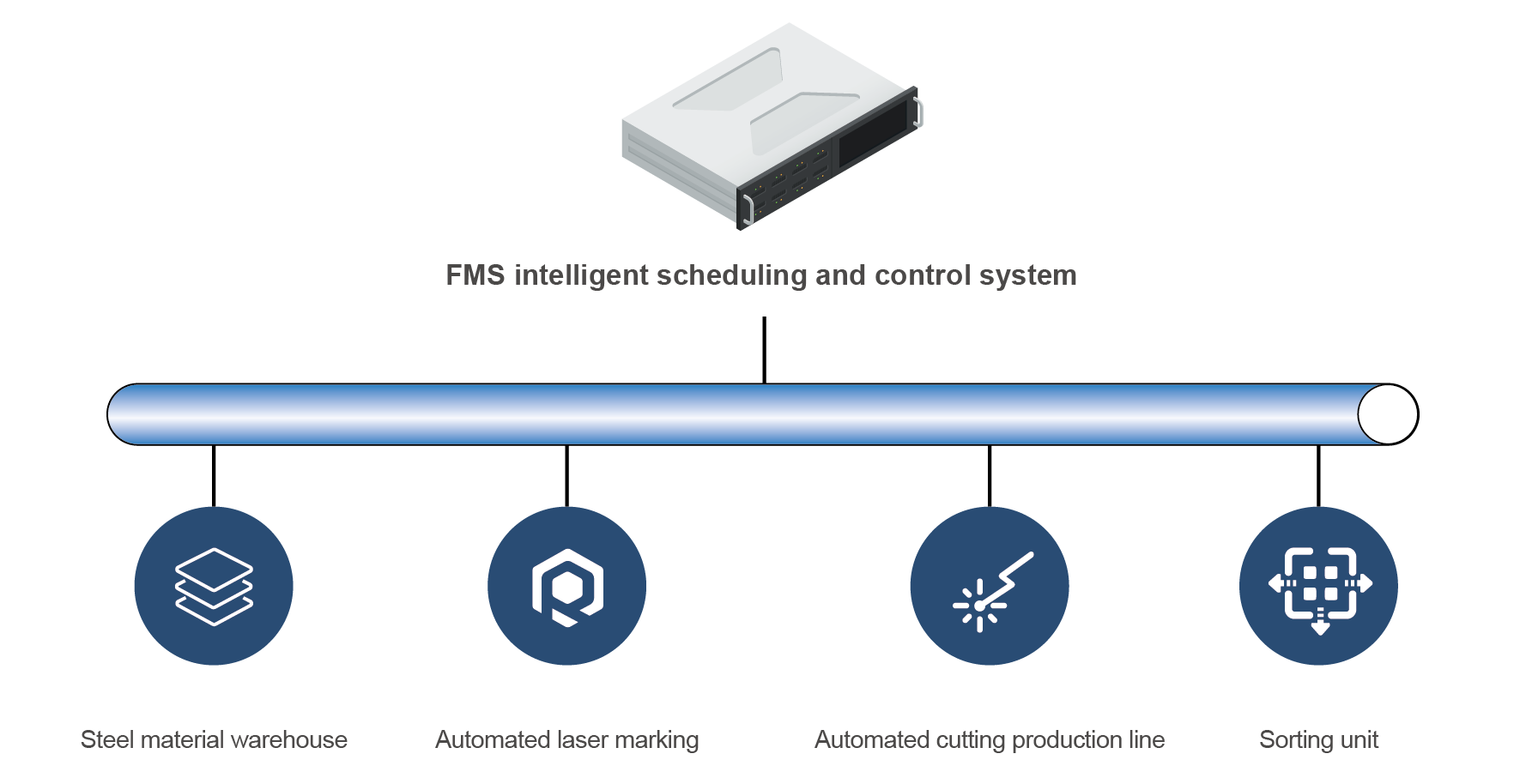

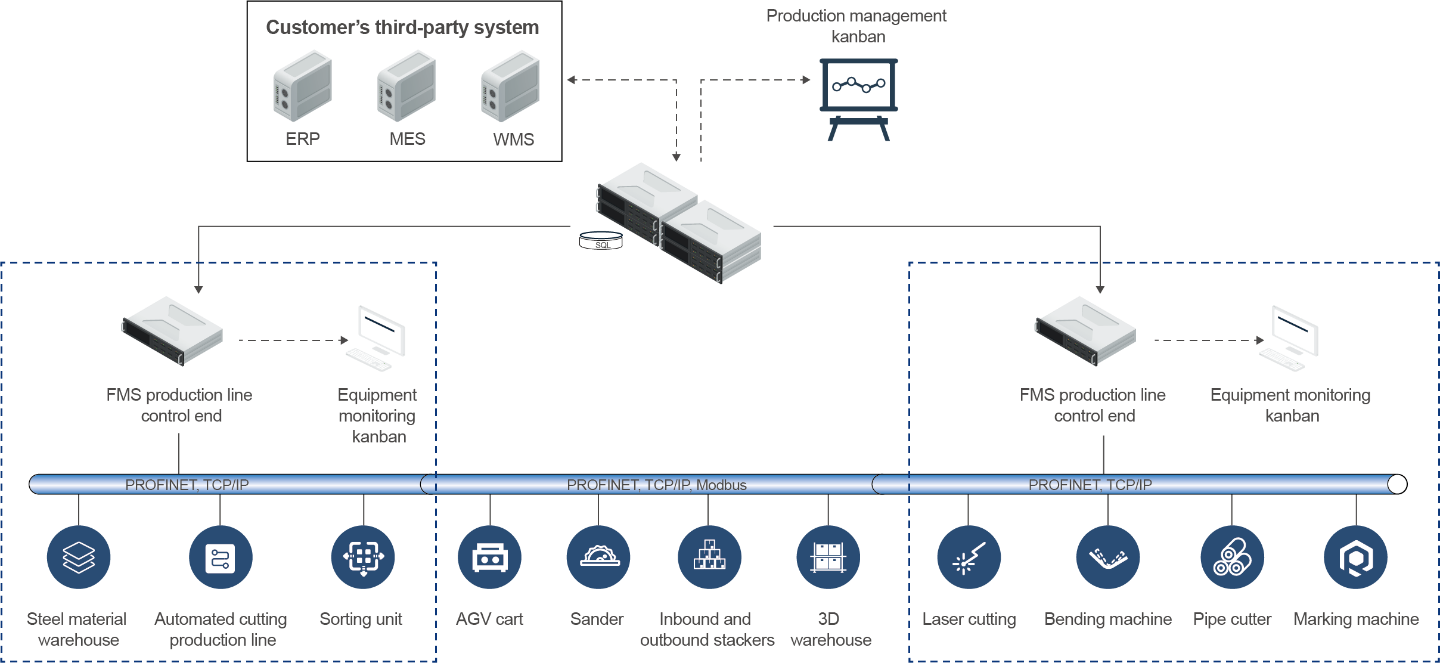

Control and Information System

The overall control system of the production line is divided into three parts: loading and unloading control system, cutting machine numerical control system and FMS intelligent scheduling and control system (optional). The loading and unloading control system controls the operation of the material warehouse, loading and unloading devices and finished product carts. The CNC system of the cutting machine implements laser cutting and automatic exchange control of the tables. The FMS intelligent scheduling and control system assigns processing tasks, schedules machine loading and unloading, adjusts the cutting machine, and cooperates with the loading and unloading system to work in an orderly and efficient manner.

Automated Loading and Unloading Control System

The automated control system of the production line adopts PLC controller and its various parts are deployed based on the ProfiNet bus protocol to form a distributed control system. The control program follows the IEC international standard, and the program structure is modular, standardized, generalized, and easy to upgrade. The system provides efficient self-diagnosis and self-processing functions and a wealth of anomaly monitoring and alarm functions. It is easy to maintain and operate.

SLU Series

Floor space (L×W×H)

Max traveling speed

Max positioning speed

Maximum size of loaded sheet

Maximum size of unloaded sheet

Control system

Maximum attraction weight

Number of electronic cart

Bearing of electronic cart

Horizontal traveling speed of e-cart

Rated power voltage

Frequency

Phase

18.5 m×5.6 m×4m

40 m/min

8 m/min

3000×1500×5

3000×1500×5

PLC control system

180 kg

2

4t

20m/min

380 V

50 Hz

3

contact us

LET’S TALK

LET’S TALK