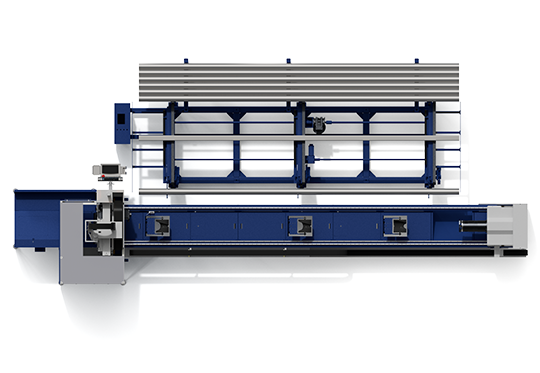

High Strength Heavy Duty Welded Machine Bed

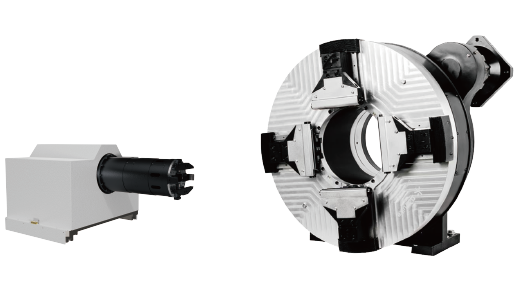

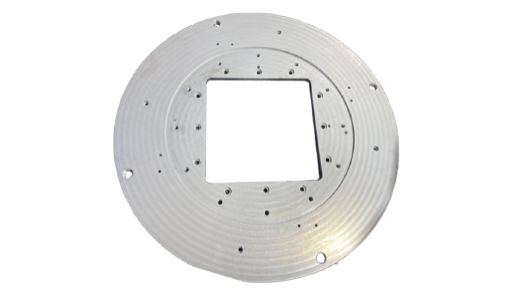

linkage Self Centering Chuck

Integrated CNC Forming Chuck

The chuck adopts overall protection to ensure no dust or waste enters the interior. The sliding block moves with precision, and the moving parts are hardened and wear-resistant, with guaranteed accuracy control. The double roller gripper has a reasonable support span and strong rigidity, ensuring stable clamping during rotation and processing accuracy.

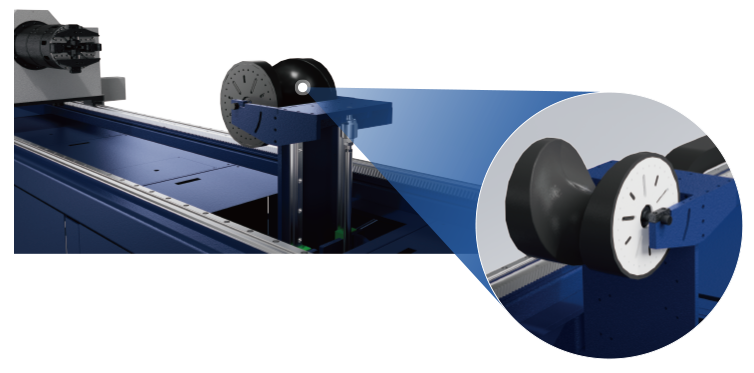

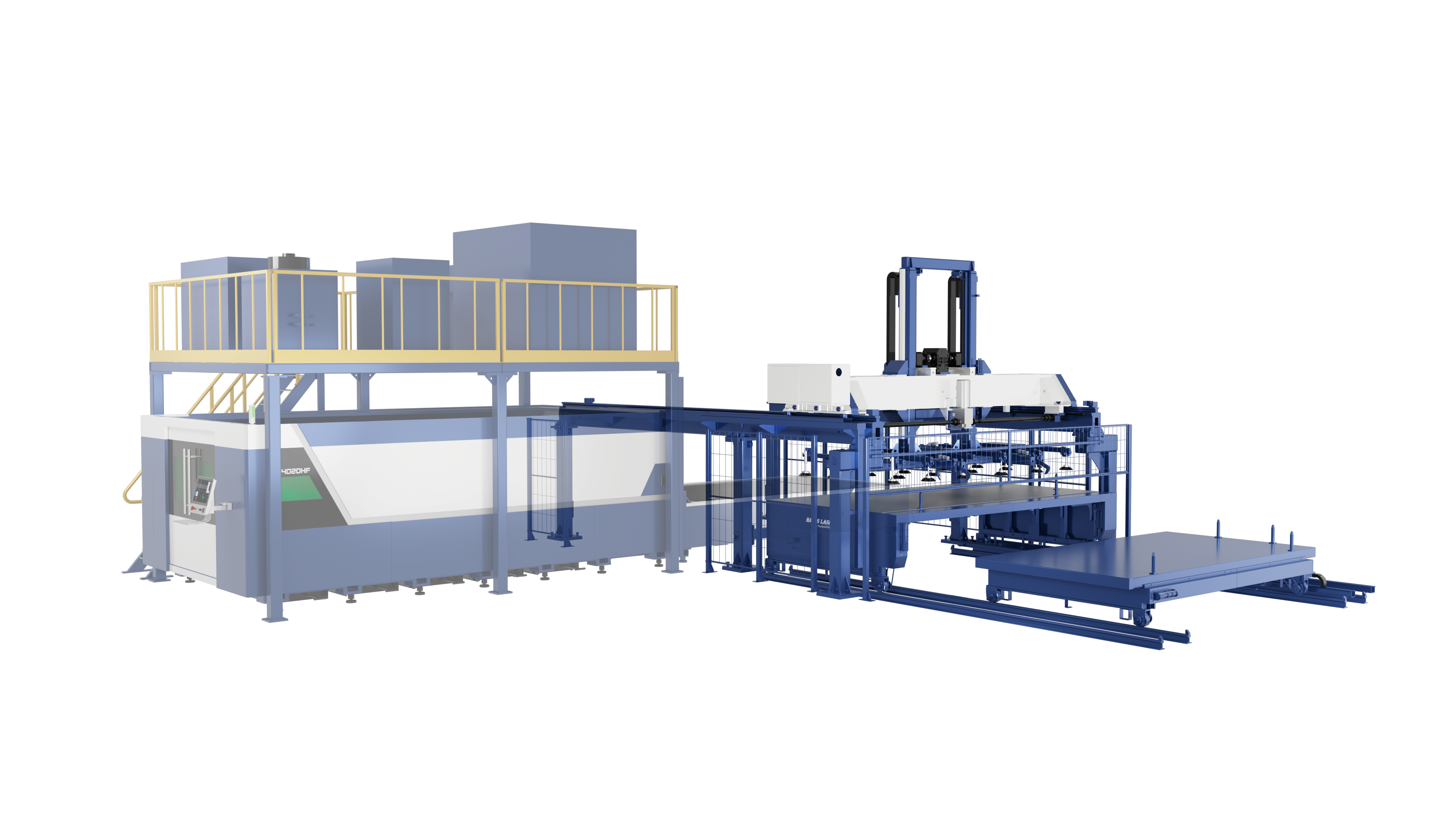

Variable Diameter Wheel Supports Loading

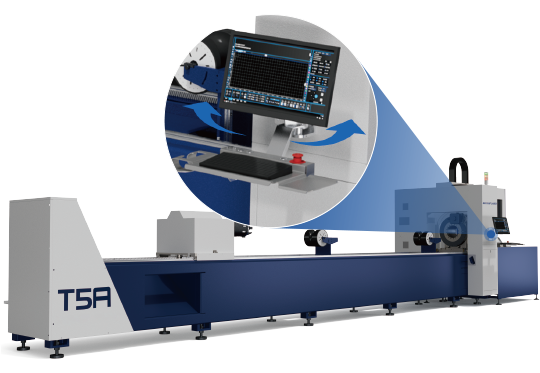

User-friendly Operation Interface

The equipment is stable, with a user-friendly operation interface, real-time feedback of processing status, fully enclosed protection of the cutting area, equipped with safety doors and visual windows to ensure the orderly progress of cutting processing.

Frog Jumping Cutting

Support frog jumping cutting, reducing the idle running time of the machine tool and improving cutting efficiency. Each perforation point saves 0.3 seconds of time.

T5 Series

Max processable pipe length

Maximum speed

Max operating acceleration

Max load capacity (single)

Tail material length

Range of material wall thickness

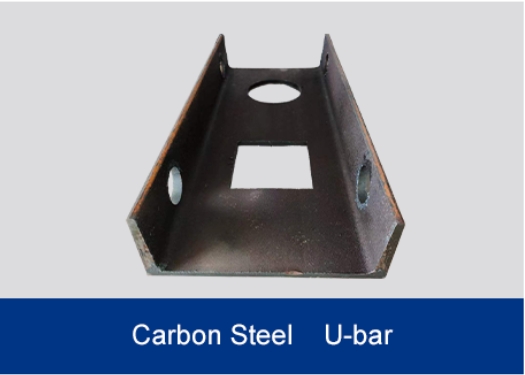

Processing capacity

≤6500mm

T5mini: 200R/min

1.0g

260kg(≤43kg/m)

≥80mm

≥0.8mm

H Beam≤8#

≤6500mm

T5: 120Rmin

1.0g

260kg(≤43kg/m)

≥80mm

≥0.8mm

H Beam≤20#

contact us

LET’S TALK

LET’S TALK