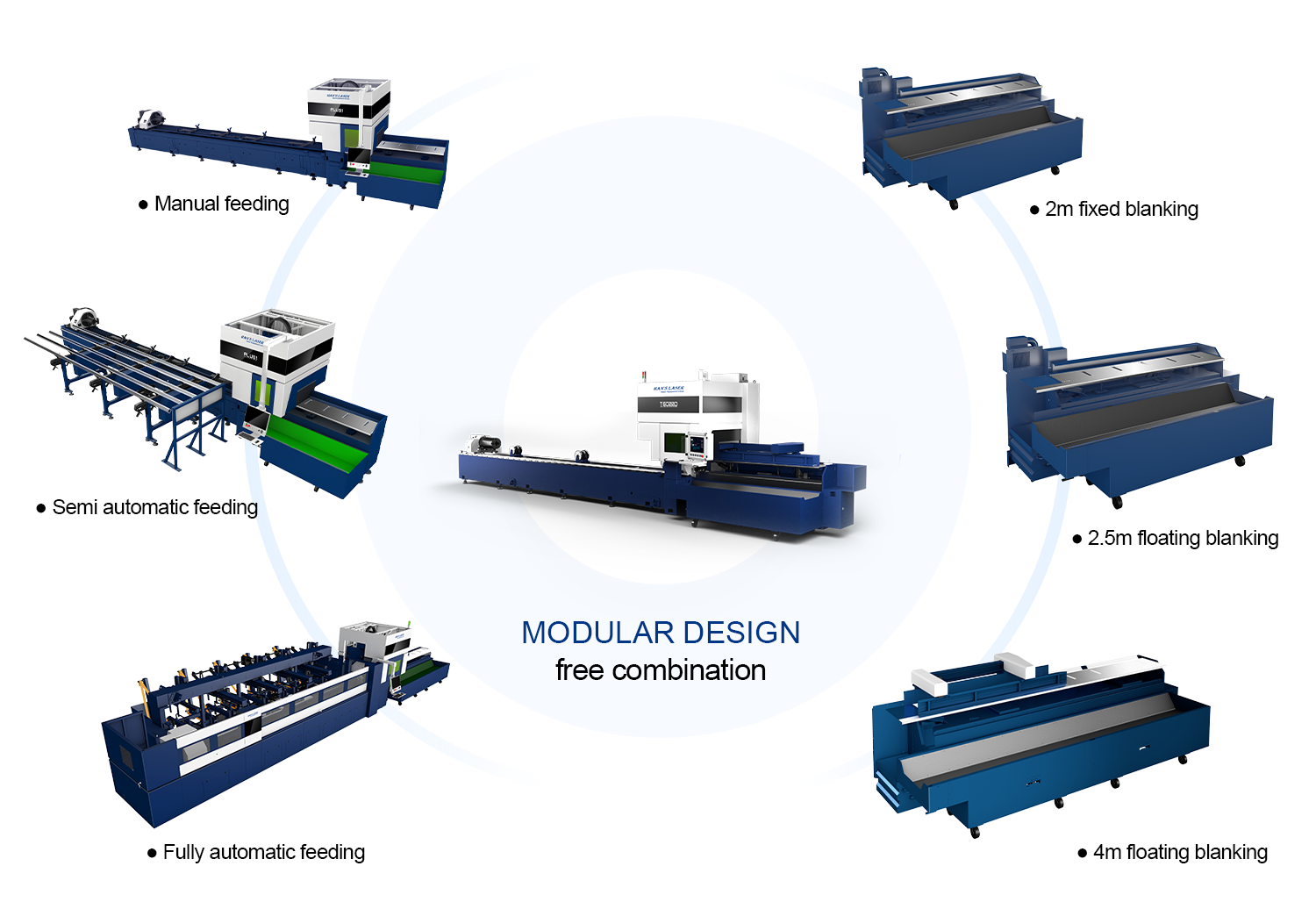

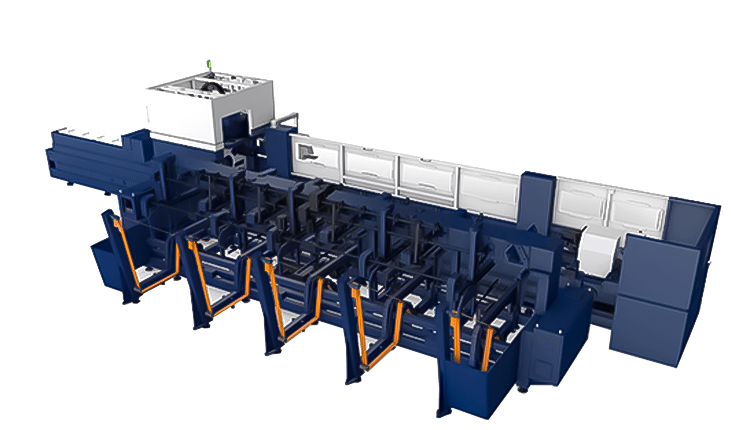

Modular Design, Flexible Combination

Han's tube laser series uses mix and match modular loading and unloading structure. This modular combination brings users munch more flexibility to fit their own needs.

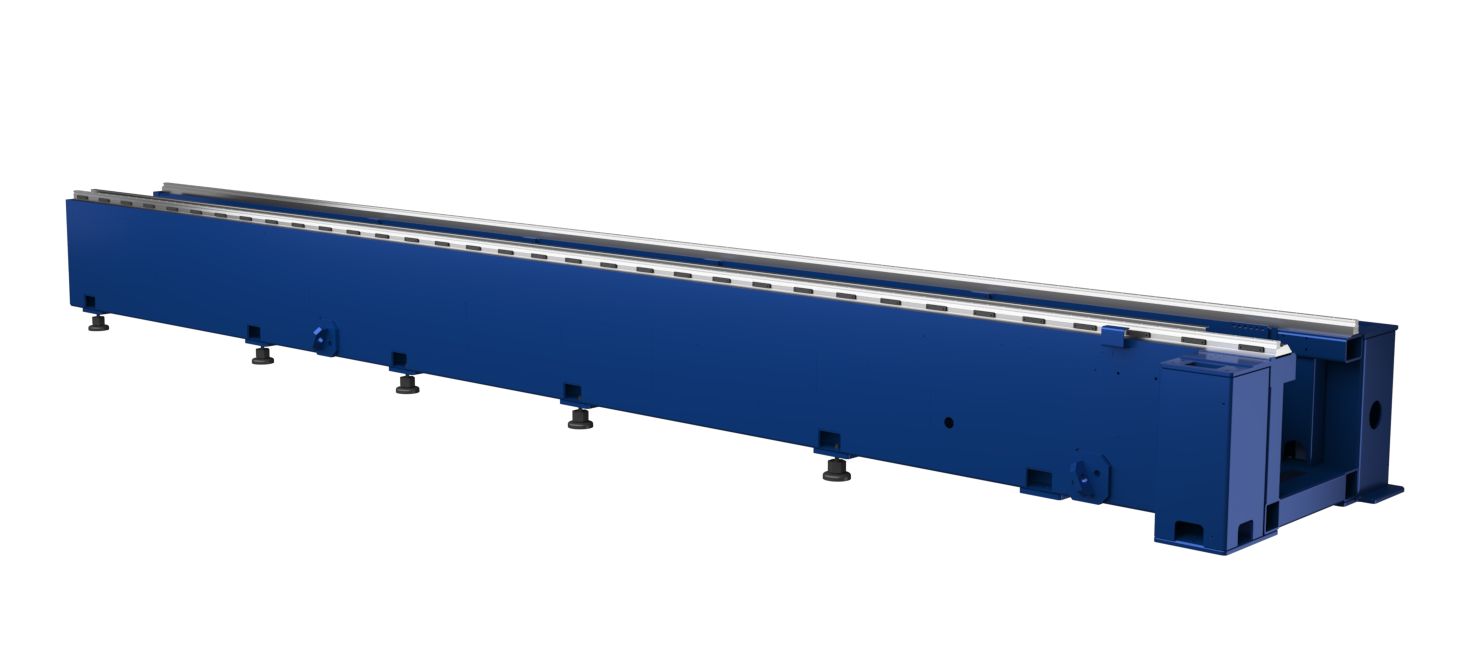

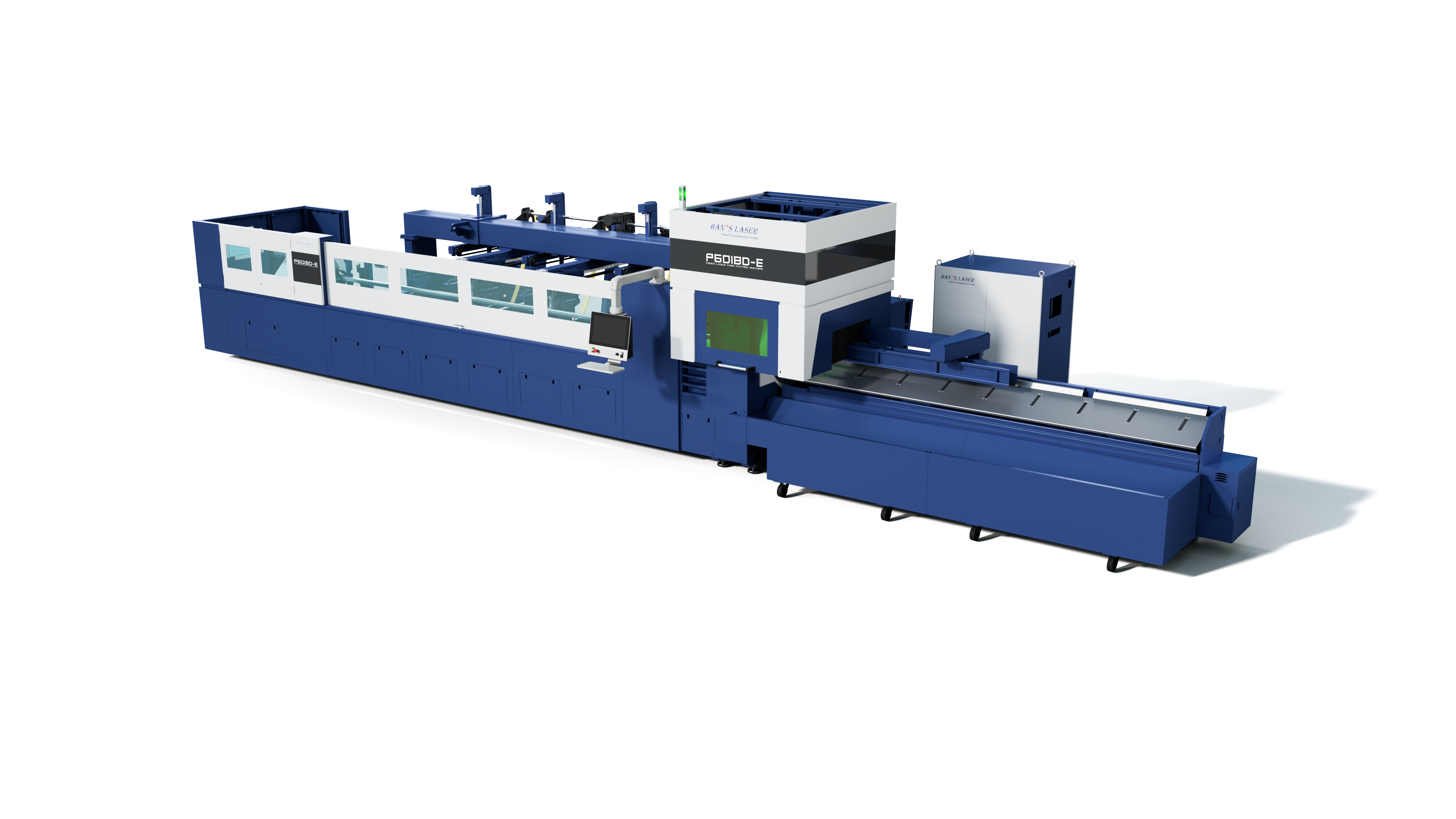

Horizontal Welding Bed

•The machine adopts horizontal structure, high-precision gear rack and linear guide rail, with stable transmission. It is equipped with blanking device, which improves the production efficiency .

•The lathe bed adopts stress-relieved welded structure. Process includes annealing, rough machining, vibration aging to eliminate residual stress, and finish machining. Ensures high rigidity, precision, and long-term stability.

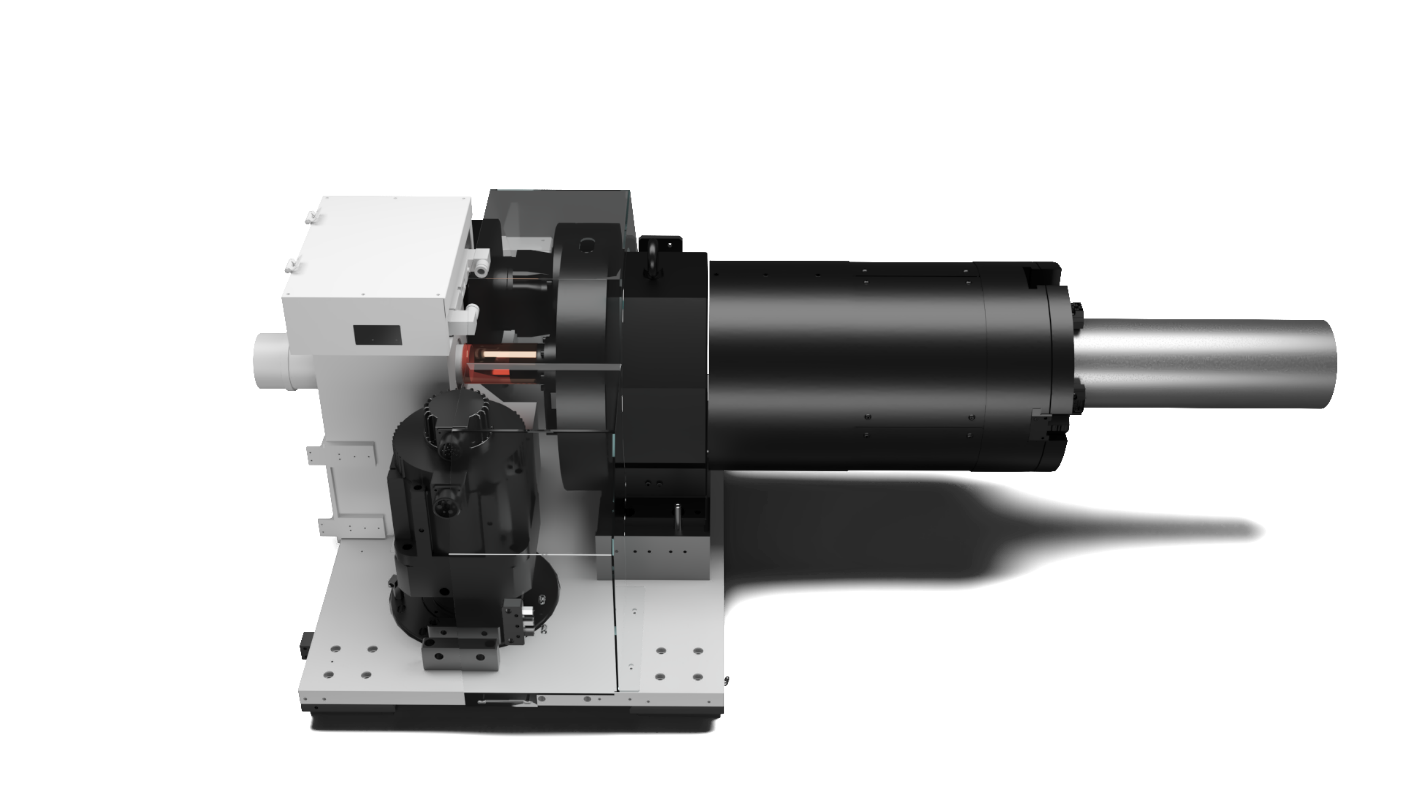

Han's Cutting Head

•Cutting Head: Capacitive sensor ensures high-precision detection and stable responsiveness.

•Drive System: X/Y/Z linear axes + A/B rotary axes utilize high-torque servo motors for high-speed, precision motion control.

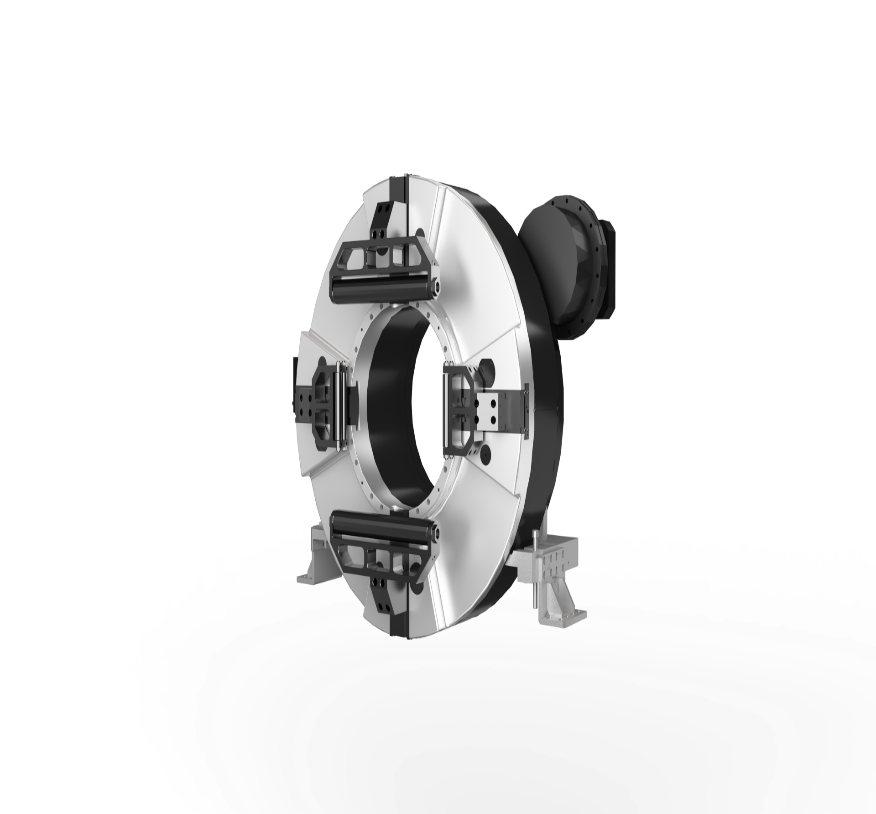

Four-Jaw Self-Centering Pneumatic Chuck

Four-claw roller pneumatic chuck with self-centering via integrated clamping-grasping mechanism. Welded plate construction for feeding and fixed chuck seats. Stress-relieved through high-temperature annealing, rough machining, vibration aging, and precision finishing. Features high rigidity, lightweight design, and superior dynamic performance.

"Negative Pressure Dedusting" in the Pipe

The pipe interior and cutting area adopt negative pressure suction dust removal, which has good dust removal effect and is clean and environmentally friendly.

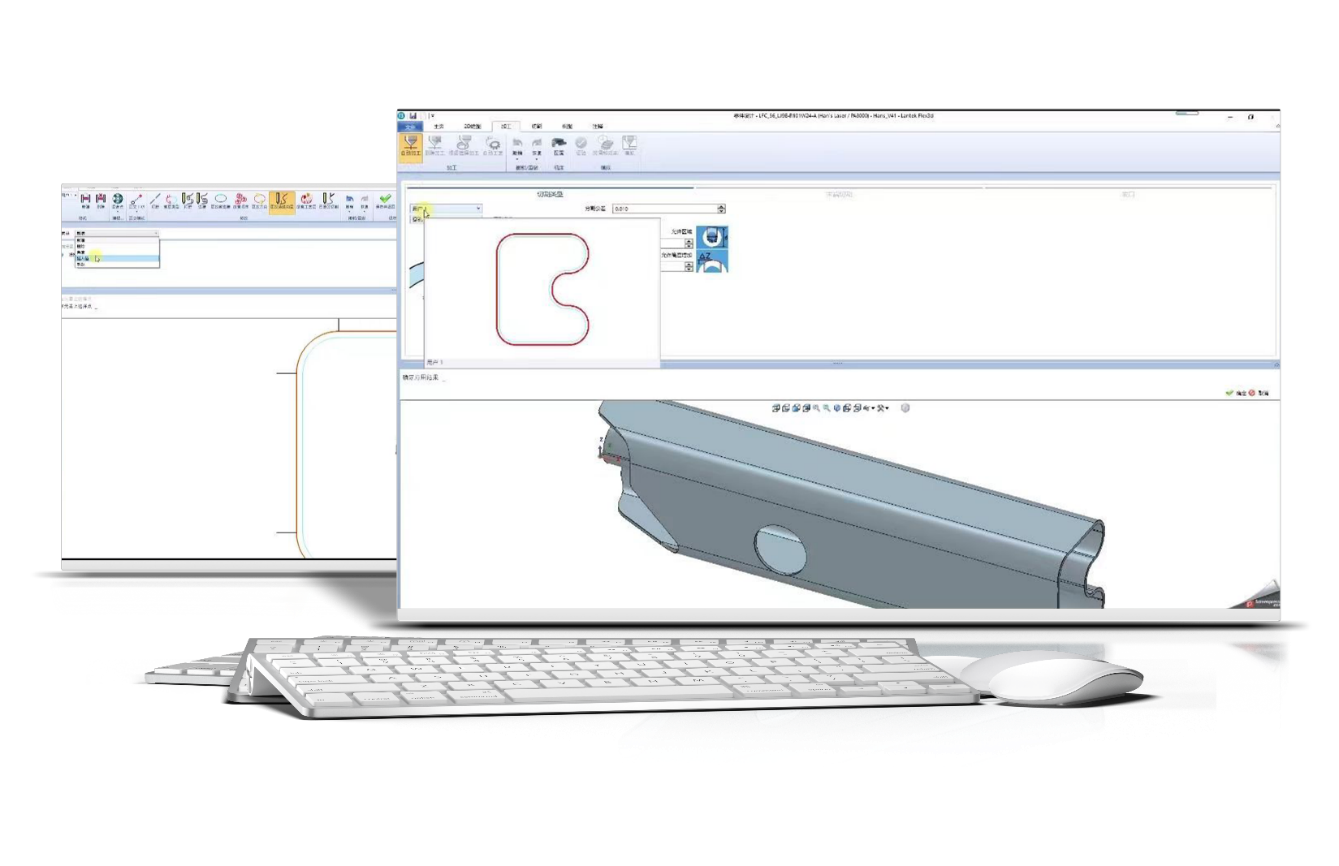

Professional Nesting Software

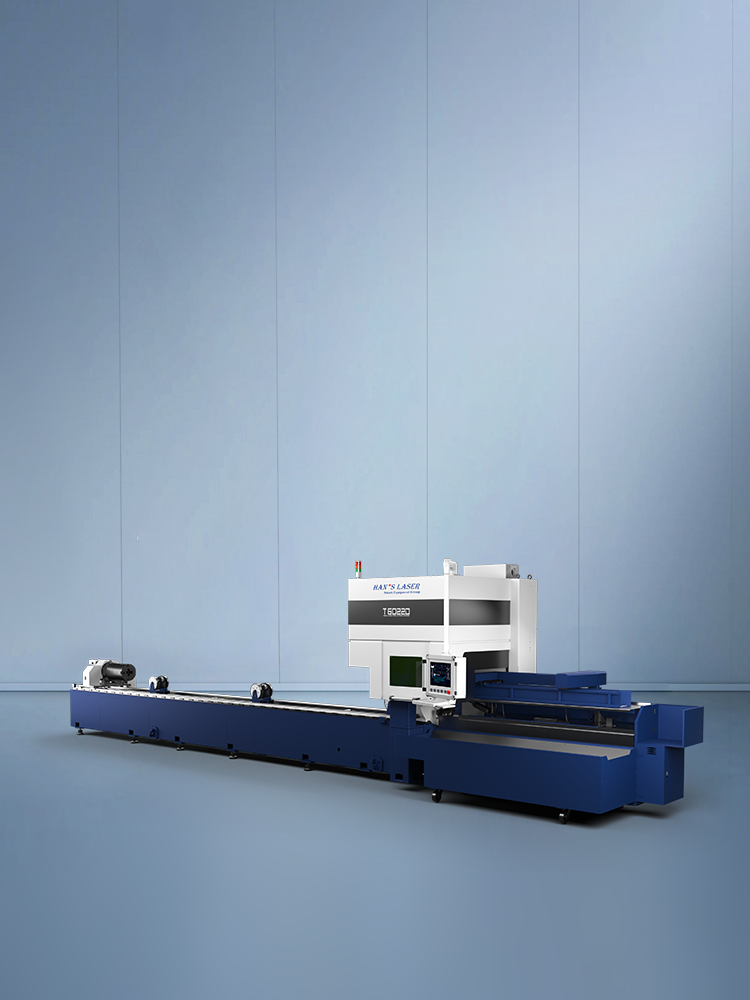

TD Series

Machine Type

Laser Source Power

Max. Machining Range

Cutting Speed

Max. Weight of Single Tube

Unload Tube Length (Custom)

Positioning Speed

T6016D /T6022D/T10025D/T6033D /T12033D/T12035D

2000w ⁄ 3000w ⁄ 4000w ⁄6000w(optional)

φ15-220 mm /φ15-150mm/φ15-254 mm/φ15-200mm/φ11-330 mm/φ10-230mm

100rpm

100kg/150kg/200kg

0-2000mm

100m/min

contact us

LET’S TALK

LET’S TALK