Our History

1996

2000

2004

2006

2009

2014

2016

2020

NOW

Event

-

2025.03.11-03.14LASER World of PHOTONICS CHINA

-

2025.02.11-02.13Expo Manufactura

-

2024.11.28-12.01BUMATEK

-

2024.10.15-10.17FABTECH

-

2024.10.08-10.10MSV2024

-

2024.10.01-10.04Machtech & Innotech Expo

-

2024.07.02-07.05MTA Vietnam 2024

-

2024.05.15-05.18MetalTech & Automex 2024

-

2024.05.07-05.11FEIMEC 2024

-

2024.04.01-04.05SIMTOS

-

2023.05.10-05.13LAMIERA

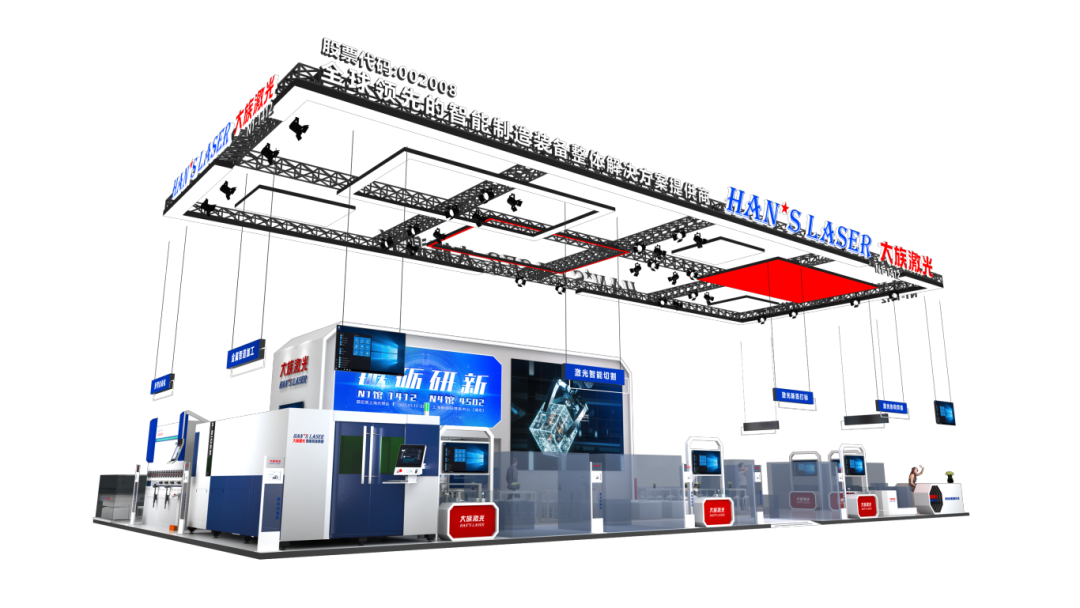

Shanghai, March 11, 2025 – The 20th LASER World of PHOTONICS CHINA has opened at the Shanghai New International Expo Centre, gathering top global exhibitors to showcase cutting-edge photonics innovations. Han’s Laser, a leader in laser technology, presents its latest solutions with an eye-catching dual-booth setup (N1-1412 & N4-4502), drawing industry attention.

LASER World of PHOTONICS CHINA

Expo Manufactura is one of Mexico's leading manufacturing trade shows, focusing on industrial innovation, automation, and advanced manufacturing technologies. Held annually in Monterrey, it gathers key industry players from sectors such as metalworking, automation, robotics, and additive manufacturing.

Expo Manufactura

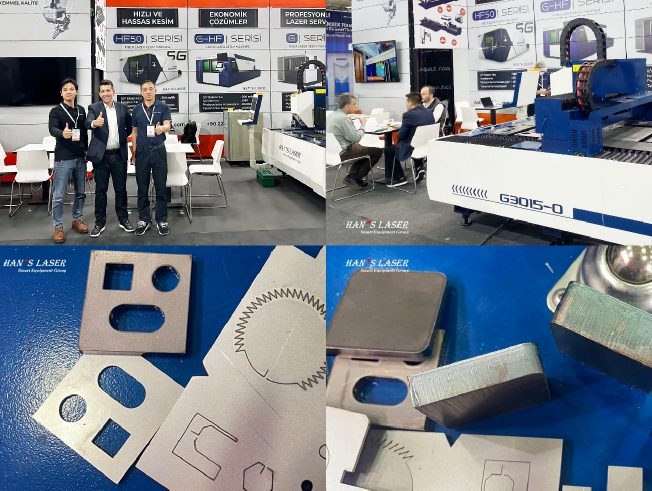

BUMATECH is the largest and most professional welding in-

dustry exhi.bition in Turkey, The exhibits displayed at the exhi-

bition include metalprocessing and forming machinery,

metal cutting equipment, specialprocessing machine tools,

welding equipment, manual, hydraulic, pneu-matic tools, digi-

tal display devices and machine tools, fixtures and related

products,inspection and measuring equipment.

BUMATEK

FABTECH is a long history, large scale and influential metal

forming exhibition in North America, which started in 1981

and is held once a year in Chicago, Las Vegas and Atlanta. lt

is a long history, large scale and influential metal forming

exhibition in North America, as well as a pipe.plate,stamping

and welding exhibition in North America.

FABTECH

MSV is the largest and most influential industrial machinery

exhibition in Central and Eastern Europe. Since it was orga-

nized in 1959,it has been the most important and the most

effective trade fair in the Czech Republic. The exhibition

covers all fields of industrial production and is one of the

international exhibitions supported by the International Exhi-

bition Alliance.

MSV2024

MachTech &InnoTech Expo is the largest international trade

fair for metalworking machinery and technology in Bulgaria.

Machtech & Innotech Expo

MTA Vietnam is the largest international precision mechani-

cal engineering and metal working exhibition in ASEAN.

MTA Vietnam 2024

Malaysia International Machine Tools and Industrial Automa-

tion Exhibition(MetalTech & Automex 2024)is Malaysia's

influential, professional and influential international trade

fair for machinery processing.Aimed at Malaysia and its

neighboring countries in the industry to create a platform for

communication and cooperation in the machinery industry.

MetalTech & Automex 2024

FElMEC is the largest and most influential machinery and

machine tool exhibition in Latin America, which attracted a

total of 900 exhibitors from 29 countries and regions around

the world. FElMEC provides an excellent opportunity for

buyers and sellers around the world to communicate with

each other face-to-face.

FEIMEC 2024

Seoul Machine Tool Show (SlMTOS) is one of the most

well-known and professional machine tool exhibitions in

Asia, founded in 1984, and is a representative exhibition for

the Korean production materials industry.

SIMTOS

Lamiera is the largest and most prestigious exhibition in ltaly

for sheet metal forming. it is organized by the ltalian Associ-

ation of Machine Tools,Robotics and Automation (UClMU).

The range of exhibits includes metal cutting machines, metal

forming machines, tools, industrial automation.accessories

and components, measuring, welding, machine and equip-

ment polishing, services, flexible manufacturing cells and

systems,research and development, environment and safety,

CAD, CAM systems,and much more.

LAMIERA

News

All

Up-coming Events

News

-

72025.04.25Han’s Laser to Showcase Laser Innovations at FABTECH Mexico 2025

72025.04.25Han’s Laser to Showcase Laser Innovations at FABTECH Mexico 2025 -

62025.03.17HAN'S LASER Showcases China's Laser Innovation Leadership at 2025 Shanghai Industry Summit

62025.03.17HAN'S LASER Showcases China's Laser Innovation Leadership at 2025 Shanghai Industry Summit -

52025.03.08Han’s Laser Invites You to the 2025 LASER World of PHOTONICS CHINA

52025.03.08Han’s Laser Invites You to the 2025 LASER World of PHOTONICS CHINA -

42025.03.01Han’s Laser & Omron Automation Partner to Boost Smart Manufacturing

42025.03.01Han’s Laser & Omron Automation Partner to Boost Smart Manufacturing -

32025.02.20Han's Laser East China Headquarters Base Phase I Officially Launched

32025.02.20Han's Laser East China Headquarters Base Phase I Officially Launched -

22024.08.30Southwest China was officially put into production.

22024.08.30Southwest China was officially put into production. -

12024.04.08National Honor: Once again Han's Laser won Manufacturing Individual Champion Award.

12024.04.08National Honor: Once again Han's Laser won Manufacturing Individual Champion Award.

Global latout

China

World

Canda

U.S.A

Mexico

Brazil

Argentina

Sweden

Finland

Estonia

Republic of Lithuania

Poland

Ukraine

Romanicia

Austria

Italy

Romanicia

Portugal

Spain

France

Czechoslovakia

United Kingdom

Netherlands

Denmark

Norway

Korea

Headquater

India

Thailand

Vietnam

The Philippines

Malaysia

Indonesia

Australia

New Zealand

Laser Process Engineer3

Department

R&D

Work place

Campus Recruitment

Number

1 people

Job Responsibilities

1. Process research of laser application, sample making

2. Process verification, welding effect analysis, optimization and improvement combined

with theory

3. Carry out laser equipment selection, test verification and output test report

according to customer needs

4. New process development verification, independent completion of experimental design,

test operation, analysis of test results, completion of test reports, etc.

4. Provide telephone technical support, and travel to solve on-site process problems

when necessary.

Job requirementst

1. Bachelor degree or above, material, laser, welding and

other related majors

2. More than one year working experience in laser application (excellent fresh graduates

can relax the requirements)

3. Material majors have the ability to analyze materials and have relevant experience in

material welding

4. Strong hands-on ability, able to independently complete experimental design,

experimental platform construction, experimental data analysis, etc.

5. Have good expressive ability, logical thinking ability, good at communication

JOIN US

Apply for a job

You are applying for a Laser Process Engineer3, please complete the

information below so that HR can know you!

*

*

*

*

Message

UPLOAD

Other

UPLOAD

SUBMIT

LET’S TALK

LET’S TALK