- Home

-

Products

Products

-

2D Laser Cutting Machine

2D Laser Cutting Machine

-

Tube Laser Cutting Machine

Tube Laser Cutting Machine

-

Bending Machine

Bending Machine

-

Laser Welding Machine

Laser Welding Machine

-

Automation

Automation

-

Large Format Laser

Large Format Laser

-

2D Laser Cutting Machine

-

Solutions

Solutions

-

Various of Cutting Functions

-

Industry Solution

-

Smart Factory

Smart Factory

-

Materials

-

Various of Cutting Functions

-

Company

- Services

- Contact

- Home

-

Products

-

Solutions

-

Company

-

News

- Han’s Laser Smart Equipment Group won "Han’s Cup" Product Design Contest

- 2023 Metal Processing Industry - Ringier Technology Innovation Awards

- Southwest China was officially put into production

- Step Into The World of AR, Augmented Reality in Laser smart manufacturing

- Han's Laser East China Regional Headquarters Base Starts Construction!

- Han's Laser East China Regional Headquarters, Hunan Han's Laser Phase II Project initiation

- Han's Laser Smart Equipment Group formulates machinery industry standards

- Han’s Laser showcases on Fabtech2021, Chicago

- Han’s Laser records 45% growth in Q2 2021 revenue

- Han’s first fiber laser cutting machine lands to Finland

- National Honor: Once again Han's Laser won Manufacturing Individual Champion Award

- Embracing the Technological Future: Han's Laser See You at the Next Shenzhen Hi-Tech Fair

- Han’s Laser H12560LBF: Advanced Laser Cutting Machine for Steel Beams, Plates, and Grooves

- Han's Laser Streamline Manufacturing with the GRC Rolled Material Laser Cutter Line

- Why Choose a Three-in-One Handheld Laser Welding Machine?

- Han's Laser East China Headquarters Base Phase I Officially Launched

- What Are the Main Applications of Laser Equipment?

- How to Cut Titanium Alloy Precisely and Efficiently with Laser Technology

- The Role of Laser Technology in Automotive Interior and Exterior Decoration

- How to Protect and Maintain Laser Equipment During Winter to Prevent Frost Damage?

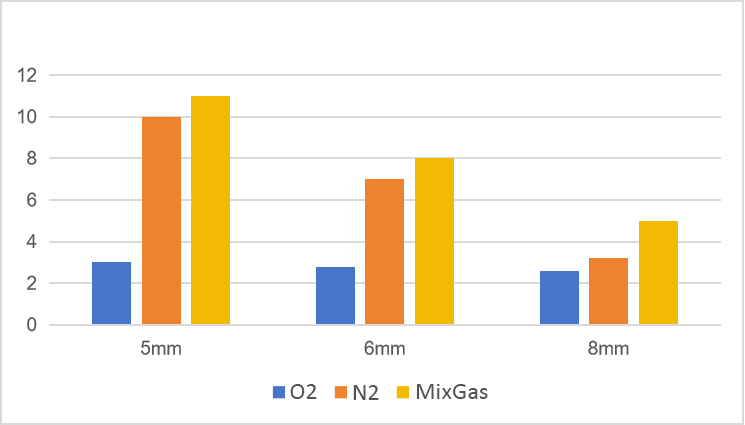

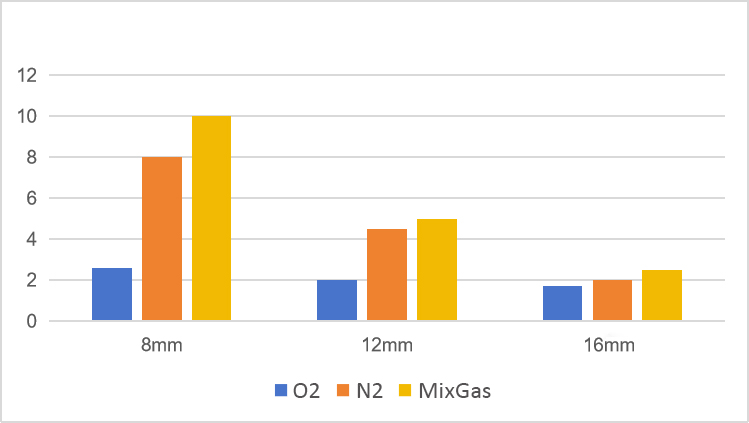

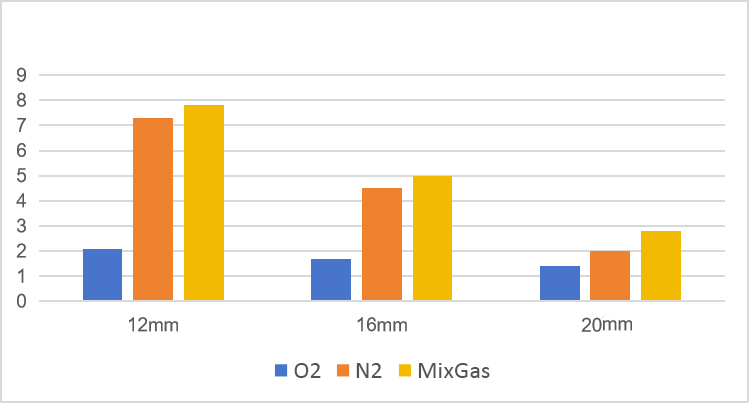

- How MixGas Technology Enhances Fiber Laser Cutting Performance

- Advanced Laser Cutting Solutions for the Special Vehicle Industry

- High-Productivity Han's 3D Laser Cutting Machine for Hot-Formed Components

- Research and Development

- Manufacturing and Quality

- Sustainability

- Career

- Industry

-

News

- Services

- Contact

Hot Keywords:

You may be looking for ...

Email

sales01@hanslaser.com

Close