- Home

-

Products

Products

-

2D Laser Cutting Machine

-

Tube Laser Cutting Machine

-

3D Laser Cutting Machine

-

Bending Machine

Bending Machine

-

Laser Welding Machine

Laser Welding Machine

-

Automation

Automation

-

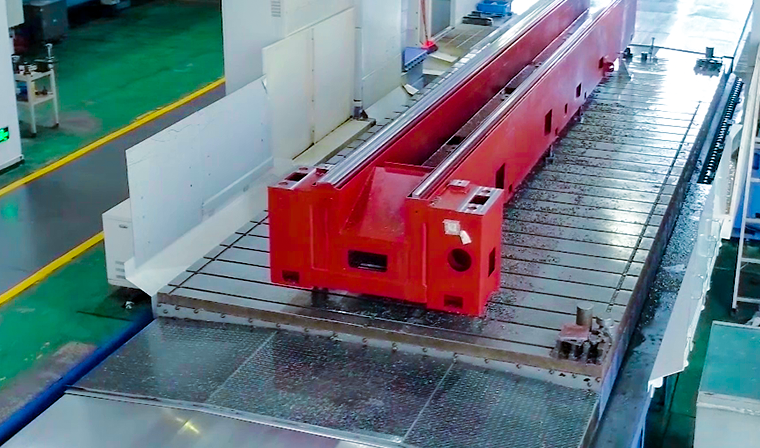

Large Format Laser

Large Format Laser

-

H Beam Laser Cutting Machine

H Beam Laser Cutting Machine

-

2D Laser Cutting Machine

- Solutions

- Company

- Services

- Contact

Hot Keywords:

You may be looking for ...

Email

sales01@hanslaser.com

Close